ಫೆಬ್ರ . 02, 2025 01:22 Back to list

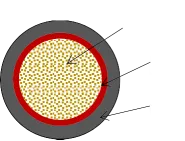

stainless steel butterfly valve

In industrial applications, the prowess of stainless steel butterfly valves is unrivaled, blending efficiency, durability, and versatility. Known for their resilient structure and superior performance, these valves are indispensable in diverse sectors, ranging from water treatment facilities to chemical processing plants. This article delves into what makes stainless steel butterfly valves a superior choice, drawing from East Ltd., a leading manufacturer renowned for their expertise and contributions to valve technology.

In real-world applications, the trustworthiness of stainless steel butterfly valves is evidenced by their long service life and minimal maintenance requirements. Their simple design results in fewer moving parts, which translates to reduced risk of mechanical failure. Industries have reported significant cost savings and enhanced system reliability following the integration of these valves, attesting to their cost-effectiveness and operational excellence. Sustainability is another dimension where stainless steel butterfly valves excel. Stainless steel is 100% recyclable, aligning with the growing demand for environmentally responsible industrial practices. Companies like East Ltd. recognize the importance of sustainable practices, ensuring their products contribute to a cleaner, greener planet without compromising on performance or safety. Moreover, the authoritativeness of East Ltd. in the valve industry is demonstrated through numerous certifications and accolades, reinforcing their commitment to excellence. Their continuous research and development efforts keep them at the cutting edge of technological advancement, continually pushing the boundaries to improve valve efficiency and performance. In conclusion, stainless steel butterfly valves represent an intersection of durability, efficiency, and sustainability. Their authoritative design and superior engineering make them a preferred choice in challenging industrial environments. With companies like East Ltd. leading the charge in innovation and quality assurance, these valves are poised to remain an essential component in numerous industrial applications for years to come, affirming their role not only as vital industrial tools but also as paragons of modern engineering efficiency and reliability.

In real-world applications, the trustworthiness of stainless steel butterfly valves is evidenced by their long service life and minimal maintenance requirements. Their simple design results in fewer moving parts, which translates to reduced risk of mechanical failure. Industries have reported significant cost savings and enhanced system reliability following the integration of these valves, attesting to their cost-effectiveness and operational excellence. Sustainability is another dimension where stainless steel butterfly valves excel. Stainless steel is 100% recyclable, aligning with the growing demand for environmentally responsible industrial practices. Companies like East Ltd. recognize the importance of sustainable practices, ensuring their products contribute to a cleaner, greener planet without compromising on performance or safety. Moreover, the authoritativeness of East Ltd. in the valve industry is demonstrated through numerous certifications and accolades, reinforcing their commitment to excellence. Their continuous research and development efforts keep them at the cutting edge of technological advancement, continually pushing the boundaries to improve valve efficiency and performance. In conclusion, stainless steel butterfly valves represent an intersection of durability, efficiency, and sustainability. Their authoritative design and superior engineering make them a preferred choice in challenging industrial environments. With companies like East Ltd. leading the charge in innovation and quality assurance, these valves are poised to remain an essential component in numerous industrial applications for years to come, affirming their role not only as vital industrial tools but also as paragons of modern engineering efficiency and reliability.

Share