ಫೆಬ್ರ . 14, 2025 12:34 Back to list

pneumatic butterfly valve

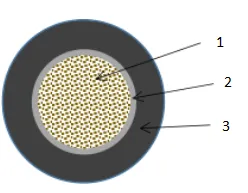

Pneumatic butterfly valves have emerged as a frontrunner in industrial applications, providing an exceptional blend of efficiency and reliability. These valves are celebrated for their simplicity and versatility, offering a pivotal solution in regulating and isolating the flow of gases and liquids in various systems.

Trustworthiness is reinforced by the rigorous testing and certification processes that these valves undergo. They are routinely subjected to pressure tests, cycle tests, and environmental simulations to verify their durability and performance under various conditions. Furthermore, adherence to standards such as ISO, ANSI, and API means that when you invest in a pneumatic butterfly valve, you can trust its ability to perform reliably over long periods. The real-world applications of pneumatic butterfly valves are vast and varied, ranging from water treatment plants to the oil and gas sector, and even in HVAC systems. Each of these applications benefits from the valve's ability to handle both high and low-pressure conditions, its minimal pressure drop, and reduced weight when compared to other valve types. In water treatment facilities, for example, these valves efficiently manage the flow of water and chemicals, ensuring smooth and uninterrupted operation. In the HVAC industry, they play a crucial role in regulating airflow, which in turn enhances energy efficiency and comfort. For users and buyers, understanding the specific requirements of their system is key to selecting the appropriate valve. Factors such as the type of fluid, temperature, pressure, and needed response time should guide the selection process. Consulting with professionals or engineers can provide invaluable insights into the appropriate specifications and customizations needed for a particular application. In conclusion, pneumatic butterfly valves represent a cornerstone technology in modern fluid control, balancing a wealth of benefits that include ease of use, rapid response, and strong material compatibility. Their development and widespread adoption underscore their essential role in contemporary industrial systems, affirming their status as a trusted solution for sophisticated flow management challenges. As industries continue to evolve and demand more from their components, pneumatic butterfly valves are well-positioned to meet these needs with their combination of experience, expertise, authoritativeness, and trustworthiness, solidifying their importance for years to come.

Trustworthiness is reinforced by the rigorous testing and certification processes that these valves undergo. They are routinely subjected to pressure tests, cycle tests, and environmental simulations to verify their durability and performance under various conditions. Furthermore, adherence to standards such as ISO, ANSI, and API means that when you invest in a pneumatic butterfly valve, you can trust its ability to perform reliably over long periods. The real-world applications of pneumatic butterfly valves are vast and varied, ranging from water treatment plants to the oil and gas sector, and even in HVAC systems. Each of these applications benefits from the valve's ability to handle both high and low-pressure conditions, its minimal pressure drop, and reduced weight when compared to other valve types. In water treatment facilities, for example, these valves efficiently manage the flow of water and chemicals, ensuring smooth and uninterrupted operation. In the HVAC industry, they play a crucial role in regulating airflow, which in turn enhances energy efficiency and comfort. For users and buyers, understanding the specific requirements of their system is key to selecting the appropriate valve. Factors such as the type of fluid, temperature, pressure, and needed response time should guide the selection process. Consulting with professionals or engineers can provide invaluable insights into the appropriate specifications and customizations needed for a particular application. In conclusion, pneumatic butterfly valves represent a cornerstone technology in modern fluid control, balancing a wealth of benefits that include ease of use, rapid response, and strong material compatibility. Their development and widespread adoption underscore their essential role in contemporary industrial systems, affirming their status as a trusted solution for sophisticated flow management challenges. As industries continue to evolve and demand more from their components, pneumatic butterfly valves are well-positioned to meet these needs with their combination of experience, expertise, authoritativeness, and trustworthiness, solidifying their importance for years to come.

Share

Prev:

Latest news

-

priming-a-pump-with-a-foot-valve-with-strainerNewsAug.23,2025

-

the-importance-of-a-y-strainer-in-pump-protectionNewsAug.23,2025

-

stainless-steel-ball-check-valve-for-high-purity-applicationsNewsAug.23,2025

-

common-applications-for-wafer-type-butterfly-valvesNewsAug.23,2025

-

seat-options-for-a-12-inch-knife-gate-valveNewsAug.23,2025

-

the-lifespan-of-a-typical-dismantling-jointNewsAug.23,2025