ಆಕ್ಟೋ . 11, 2024 10:45 Back to list

Concentric Lug Type Butterfly Valve Overview and Applications in Fluid Control Systems

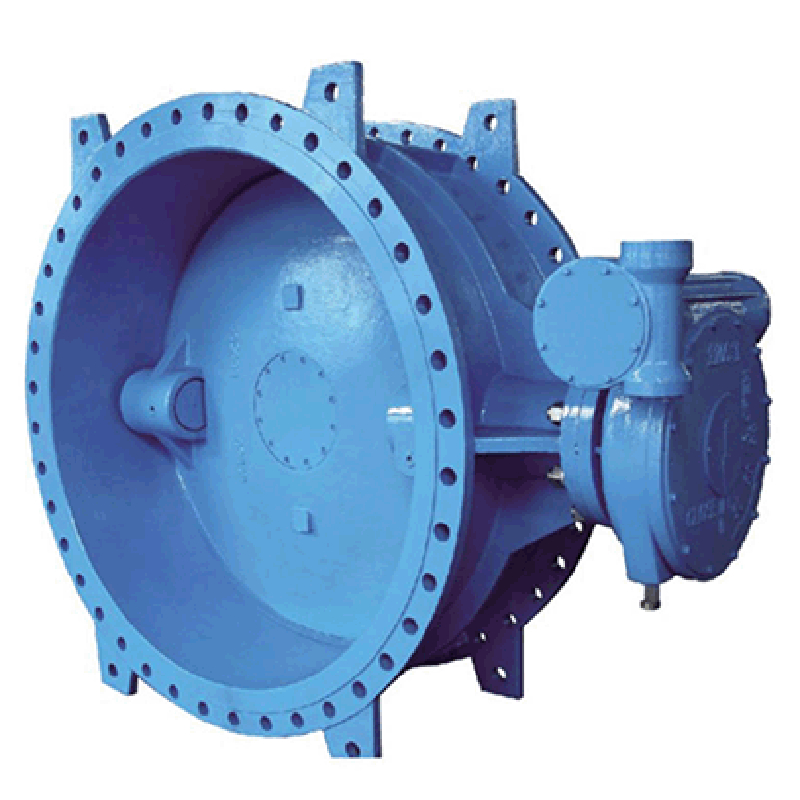

Concentric Lug Type Butterfly Valve A Comprehensive Overview

Butterfly valves are essential components in various fluid control systems, playing a crucial role in regulating the flow of liquids and gases. Among the various types of butterfly valves, the concentric lug type stands out for its unique design and functionality. This article explores the features, benefits, applications, and installation considerations associated with concentric lug type butterfly valves.

Understanding the Concentric Lug Type Design

A concentric lug type butterfly valve operates through a simple yet effective mechanism. The valve consists of a circular disc or butterfly that rotates around a central shaft, located at the same axial point as the pipe. The term concentric refers to this alignment, which allows for a uniform distribution of pressure across the valve body. The lug feature denotes the valve's integrated lugs that enable it to be bolted directly to the piping system without requiring a flanged connection.

This design is particularly advantageous in situations where installation space is limited or where a lightweight valve is desired. The lug feature facilitates easy installation and maintenance, as the valve can be removed from the line without cutting pipes, making it ideal for temporary applications or maintenance access.

Key Benefits

1. Space Efficiency Concentric lug type butterfly valves are compact, allowing for installation in tight spaces where larger valves may not fit.

2. Weight Reduction The lightweight design reduces the overall weight of the piping system, making it easier to handle during installation and minimizing the load on supporting structures.

3. Ease of Operation These valves require minimal torque to operate, thanks to their design, which reduces wear and tear on the actuator. This feature contributes to the longevity of the valve, making it a cost-effective choice.

5. Low Flow Resistance The circular design of the disc allows for smooth, unobstructed flow, significantly reducing the pressure drop compared to other valve types.

concentric lug type butterfly valve

Applications

The concentric lug type butterfly valve is widely utilized across numerous industries due to its versatility. Key applications include

- Water Treatment Plants For regulating the flow of water and various chemicals used in treatment processes. - HVAC Systems To control airflow in heating, ventilation, and air conditioning systems. - Chemical Processing In handling corrosive or hazardous fluids, thanks to the availability of various material options for the valve body and lining. - Food and Beverage Ensuring hygiene in fluid transport, as many designs are compliant with food safety standards.

Installation Considerations

When installing concentric lug type butterfly valves, several factors should be taken into account

1. Orientation Ensure that the valve is installed in the correct orientation according to the manufacturer’s specifications, as this affects performance and longevity.

2. Sealing Proper sealing in the bolted connections is critical to prevent leaks. It is advisable to use appropriate gasket materials compatible with the fluid being transported.

3. Maintenance Access Since the lug design allows for quick removal, ensure that adequate space is available for maintenance activities.

4. Temperature and Pressure Ratings Always check the temperature and pressure ratings of the valve and ensure they are suitable for the specific application to avoid complications during operation.

Conclusion

Concentric lug type butterfly valves offer a blend of efficiency, simplicity, and versatility, making them a preferred choice across various applications. Their unique design allows for easy installation, operation, and maintenance, while their ability to handle diverse media enhances their utility in different industries. Understanding the functionality and advantages of these valves can ensure optimal performance in fluid control systems, leading to improved operational efficiency and reduced downtime.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025