ನವೆಂ . 08, 2024 03:49 Back to list

Innovative Design and Applications of Bidirectional Knife Gate Valves in Modern Industry

Understanding Bidirectional Knife Gate Valves Features and Applications

Bidirectional knife gate valves are essential components in various industrial applications, particularly in environments where reliable isolation and control of bulk materials, slurries, or liquids are required. These valves serve a crucial role in managing flow within pipelines, and understanding their design, functionality, and applications can help industries optimize their processes and improve efficiency.

Design Features

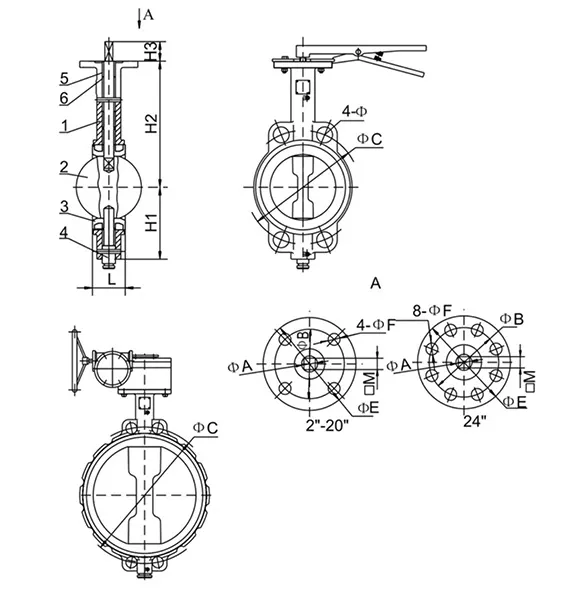

The bidirectional knife gate valve is designed with a flat blade-like gate that can effectively slice through and control the flow of materials in both directions. This design allows for versatility in installations since the valve can be used in either direction without affecting its performance. The blade is typically made from durable materials resistant to wear and corrosion, ensuring longevity and reliability in demanding environments.

One of the main components of a knife gate valve is the actuator, which can be manual or automated. Manual actuators may include handwheels or levers, while automated versions can be actuated by pneumatic, electric, or hydraulic systems. The choice of actuator often depends on the specific application, installation constraints, and the operating environment.

The simplicity of the valve's design generally means that it can be easily maintained. Unlike other valve types, such as globe or ball valves, which have intricate internal components, knife gate valves are less prone to clogging and wear, making maintenance less frequent and straightforward.

Operational Principle

The operational principle of a bidirectional knife gate valve is relatively straightforward. When the actuator is engaged, the gate moves vertically between the fully open and fully closed positions. In the fully open position, the blade retracts completely from the flow path, allowing for unobstructed flow through the pipeline. Conversely, in the closed position, the blade descends and seals against a seat, effectively providing isolation in both flow directions.

This characteristic of bidirectionality allows for greater flexibility in pipeline design, as it mitigates the need for separate valves for upstream and downstream control. As a result, industries can streamline their operations, reducing the number of components required in their systems.

bidirectional knife gate valve

Applications

Bidirectional knife gate valves find applications across numerous industries, including

1. Water and Wastewater Treatment In treatment plants, these valves are crucial for managing the flow of water and sewage. They are often used in sluice applications to control the movement of solids and liquids.

2. Mining and Mineral Processing The robust design of knife gate valves makes them ideal for handling slurries and abrasive materials commonly found in mining operations. They help in controlling the flow of minerals and facilitating processes such as dewatering.

3. Pulp and Paper Industry In this sector, bidirectional knife gate valves are utilized for pulp flow control, chemical handling, and process isolation, contributing to efficient production cycles.

4. Food and Beverage In the food processing industry, these valves help in managing the flow of various ingredients while ensuring that hygiene and safety standards are maintained.

5. Chemical Processing The chemical industry often requires valves that can withstand harsh conditions. Knife gate valves can effectively handle corrosive substances and are used in various chemical applications.

Conclusion

Bidirectional knife gate valves are critical components in modern industrial systems, providing efficient and reliable flow control for a wide range of processes. Their unique design, capable of functioning in both flow directions, offers versatility that is particularly advantageous in complex piping systems. As industries continue to seek ways to improve efficiency, reduce maintenance, and ensure safety, the role of bidirectional knife gate valves is expected to grow in significance. Understanding their features and applications can empower engineers and operators to make informed decisions that enhance operational efficiency and reduce downtime in their processes.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025