វិច្ឆិកា . 21, 2024 14:45 Back to list

y type strainer

Understanding Y-Type Strainers A Key Component in Fluid Systems

In various industrial applications and systems, maintaining the integrity of fluid flow is crucial. This is where Y-type strainers come into play. A Y-type strainer is a fundamental piece of equipment used to filter out contaminants from liquids and gases. Its unique design, shaped like the letter Y, provides multiple advantages that make it an essential component in many fluid handling systems.

What is a Y-Type Strainer?

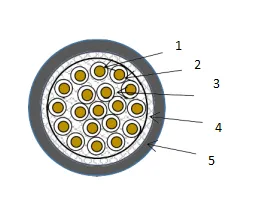

A Y-type strainer is a type of filtration device typically installed in pipelines to protect pumps, valves, and other equipment from debris and sediment that could cause damage or impair functionality. It is designed to trap unwanted solids while allowing the flow of the liquid or gas to continue smoothly. The strainer consists of a Y-shaped body, a straining element (filter), and two ends for connecting to the pipeline.

Key Features and Benefits

1. Effective Filtration The primary function of a Y-type strainer is to prevent larger particles, such as rust, dirt, and other impurities, from entering the system. This filtration process protects downstream equipment, thereby extending its lifespan and reducing maintenance costs.

2. Versatile Design Y-type strainers can be used in a variety of applications, from water treatment plants to chemical processing and HVAC systems. They are manufactured from diverse materials, including stainless steel, bronze, and plastic, allowing them to handle various fluids and system pressures.

3. Ease of Maintenance One significant advantage of Y-type strainers is their ease of maintenance. They are equipped with a removable straining element that can be cleaned or replaced without having to remove the entire unit from the pipeline. This feature minimizes downtime and operational interruptions.

y type strainer

4. Flow Direction The Y-type design allows for a compact installation while maintaining efficient flow characteristics. The angle of the strainer facilitates a smooth flow path, reducing pressure drops and ensuring optimal performance.

5. Cost-Effective Solution By preventing costly equipment failures and the need for extensive repairs, Y-type strainers represent a cost-effective solution for many industries. They can significantly reduce the operational costs associated with maintaining fluid systems.

Applications of Y-Type Strainers

Y-type strainers are commonly employed in a variety of sectors

- Water Treatment Protecting pumps and filtration systems from sediments and debris. - Oil and Gas Safeguarding equipment from solid contaminants that could disrupt operations. - HVAC Systems Ensuring clean cooling and heating fluids for efficient system performance. - Food and Beverage Filtering out impurities in fluid processes to maintain product quality and safety.

Conclusion

In summary, Y-type strainers are vital components in fluid systems across numerous industries. Their unique design and efficient filtration capabilities help protect equipment, enhance performance, and reduce maintenance costs. As the need for reliable and efficient fluid management continues to grow, understanding the benefits and functionalities of Y-type strainers is essential for engineers and industry professionals. By incorporating Y-type strainers into fluid systems, companies can ensure smoother operations and longer-lasting equipment, ultimately leading to higher efficiency and lower operational costs. As industries evolve and technologies advance, the role of Y-type strainers will remain significant in maintaining the integrity and efficiency of fluid management systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025