វិច្ឆិកា . 16, 2024 03:50 Back to list

Wafer Butterfly Valve Manufacturing Facility Overview and Production Insights

The Wafer Butterfly Valve Factory A Commitment to Precision Engineering

In the realm of industrial applications, the wafer butterfly valve has emerged as a vital component, serving various sectors such as water treatment, chemical processing, and HVAC systems. At the heart of this innovation is the wafer butterfly valve factory, where precision engineering and state-of-the-art manufacturing practices converge to produce high-quality valves designed for efficiency, durability, and performance.

The design of wafer butterfly valves is distinct yet functional. Unlike traditional valves that require extensive installation space, the wafer-bodied design allows for a more compact installation between flanges, significantly saving space and reducing material costs. This innovative design has made wafer butterfly valves increasingly popular in modern industrial applications, where space constraints are a significant concern.

The factory’s commitment to quality begins with the selection of raw materials. The production process typically involves using robust materials such as stainless steel, cast iron, and various alloys that can withstand corrosion and high-pressure conditions. Through meticulous quality control, every stage of production ensures that the valves not only meet but exceed industry standards.

Advanced manufacturing techniques are employed in the wafer butterfly valve factory, which encompass computer numerical control (CNC) machining and precision casting. These technologies allow for the creation of intricate designs and accurate dimensions, vital for the proper functioning of the valves. Furthermore, by investing in advanced automation and robotics, the factory enhances productivity while maintaining consistency in quality.

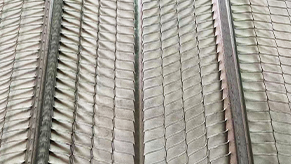

wafer butterfly valve factory

Testing and validation are critical phases in the manufacturing process. Each valve undergoes rigorous testing to assess its functionality, pressure tolerance, and leakage integrity. This thorough evaluation guarantees that only the most reliable products reach the market, instilling confidence in customers who depend on these components for critical operations.

In addition to production, the wafer butterfly valve factory also emphasizes customized solutions. By collaborating closely with clients, the factory can design valves that meet specific operational requirements, further enhancing the value offered to its customers.

As industries continue to evolve, the wafer butterfly valve factory remains at the forefront, adapting to new technology and customer needs. With a focus on sustainability, they are increasingly incorporating eco-friendly practices and materials, contributing to a greener future.

In conclusion, the wafer butterfly valve factory is not just a manufacturing facility; it is a hub of innovation where engineering meets practicality. Through a commitment to quality, advanced technology, and customer collaboration, it plays a crucial role in supporting various industries with reliable and efficient valve solutions.

Share

-

priming-a-pump-with-a-foot-valve-with-strainerNewsAug.23,2025

-

the-importance-of-a-y-strainer-in-pump-protectionNewsAug.23,2025

-

stainless-steel-ball-check-valve-for-high-purity-applicationsNewsAug.23,2025

-

common-applications-for-wafer-type-butterfly-valvesNewsAug.23,2025

-

seat-options-for-a-12-inch-knife-gate-valveNewsAug.23,2025

-

the-lifespan-of-a-typical-dismantling-jointNewsAug.23,2025