ធ្នូ . 26, 2024 20:18 Back to list

Teflon-Coated Butterfly Valve for Enhanced Performance and Durability in Fluid Control Applications

The Versatility of Teflon Butterfly Valves A Comprehensive Overview

Butterfly valves are a critical component in a multitude of industrial applications, primarily used for regulating or isolating flow in various systems. Among the many types of butterfly valves, Teflon butterfly valves stand out for their unique properties and advantages, making them a preferred choice in specific environments.

What is Teflon?

Teflon is a brand name for a polymer known scientifically as polytetrafluoroethylene (PTFE). This material is renowned for its exceptional non-stick properties, high resistance to chemical reactions, and ability to withstand extreme temperatures. Teflon's unique characteristics make it an excellent choice for valve applications, especially in industries that handle corrosive substances or operate under severe conditions.

Advantages of Teflon Butterfly Valves

1. Corrosion Resistance Teflon butterfly valves are highly resistant to a wide range of chemicals, including acids, bases, and solvents. This property is particularly beneficial for industries such as chemical processing, pharmaceuticals, and food processing, where chemical compatibility is crucial.

2. Temperature Tolerance Teflon can withstand temperatures ranging from -450°F to +500°F (-268°C to +260°C), making Teflon butterfly valves suitable for high-temperature applications. This thermal stability ensures that the valve maintains its integrity in demanding environments.

3. Low Friction The non-stick nature of Teflon leads to lower friction in the valve mechanism. This results in smoother operation, reduced wear, and less energy required to operate the valve, contributing to overall system efficiency.

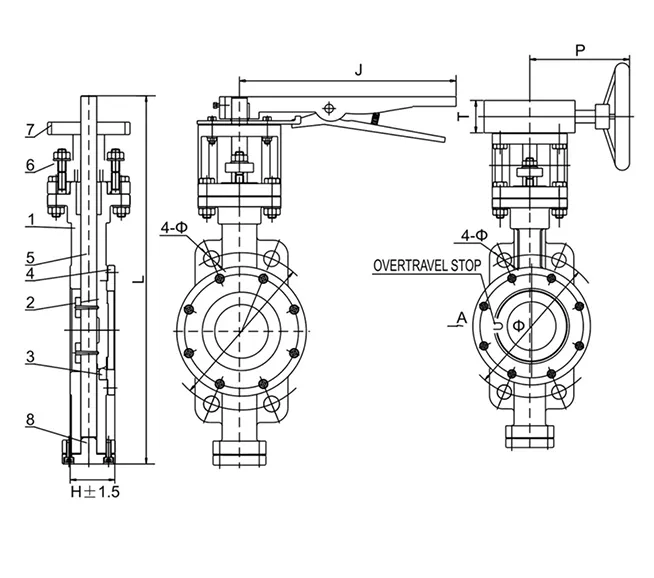

teflon butterfly valve

4. Lightweight and Durable Despite their robust performance characteristics, Teflon butterfly valves are relatively lightweight. This quality facilitates easier installation and reduces the load on supporting structures. Additionally, Teflon’s durability ensures a longer service life, which can lead to lower maintenance costs.

5. Versatile Applications Teflon butterfly valves are suitable for a wide array of applications, including but not limited to, water treatment, oil and gas, steam, and food and beverage processing. They can be employed in both on-off applications and throttling service, enhancing their versatility.

Design and Functionality

Teflon butterfly valves consist of a circular disc that rotates about a central axis. The disc operates in a quarter-turn motion, allowing it to either fully open or close the flow path. The Teflon lining or seat provides a tight seal when the valve is closed, preventing leakage and ensuring efficient flow management.

The simplicity of the design also means that Teflon butterfly valves can be operated manually or automatically, depending on the specific needs of the system. This adaptability can improve the efficiency of operations and enhance overall safety in industrial processes.

Conclusion

The adoption of Teflon butterfly valves in various industries continues to grow, primarily due to their unique characteristics that offer significant advantages over traditional valve materials. Their corrosion resistance, temperature tolerances, low friction properties, and versatility make them an ideal choice for many applications. As industries increasingly seek efficient, durable, and safe fluid control solutions, Teflon butterfly valves will undoubtedly remain a vital component in state-of-the-art systems.

In summary, Teflon butterfly valves provide an exemplary solution for managing flow in challenging environments, and their innovative design continues to evolve, adapting to the ever-changing demands of modern industry.

Share

-

priming-a-pump-with-a-foot-valve-with-strainerNewsAug.23,2025

-

the-importance-of-a-y-strainer-in-pump-protectionNewsAug.23,2025

-

stainless-steel-ball-check-valve-for-high-purity-applicationsNewsAug.23,2025

-

common-applications-for-wafer-type-butterfly-valvesNewsAug.23,2025

-

seat-options-for-a-12-inch-knife-gate-valveNewsAug.23,2025

-

the-lifespan-of-a-typical-dismantling-jointNewsAug.23,2025