វិច្ឆិកា . 12, 2024 09:44 Back to list

swing check valve factory

Understanding Swing Check Valve Factories A Comprehensive Overview

Swing check valves are critical components in various industrial applications, ensuring that fluids flow in one direction and preventing backflow. The production of these valves is a sophisticated process that requires precision, high-quality materials, and adherence to strict industry standards. In this article, we explore the operational dynamics of swing check valve factories, their significance in various industries, and the manufacturing processes involved.

The Importance of Swing Check Valves

Swing check valves are widely used in industries such as water supply, wastewater management, oil and gas, power generation, and chemical processing. Their primary function is to safeguard systems by allowing fluid to flow in a single direction while preventing backflow, which can lead to contamination or damage to equipment. The reliability and efficiency of these valves are crucial for maintaining operational integrity in pipelines and other fluid transport systems.

Manufacturing Process

The manufacturing process of swing check valves involves several key stages to ensure the final product meets the required specifications and quality standards

.1. Material Selection The first step in manufacturing swing check valves is selecting the appropriate materials. Common materials include cast iron, stainless steel, and bronze. The choice depends on the application, temperature, and pressure requirements. Factories ensure that materials are sourced from reputable suppliers that meet industry certifications.

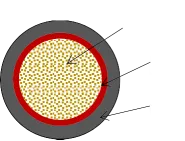

2. Casting and Forging The chosen materials undergo casting or forging to create the valve body and components. In casting, molten metal is poured into molds, while forging involves shaping the metal into desired forms through compressive forces. Both methods are used to create durable and robust valve bodies capable of withstanding high pressures and temperatures.

3. Machining After casting or forging, the valve components are machined to achieve precise dimensions. This process involves cutting, drilling, and milling to create the necessary fittings and surfaces for sealing mechanisms. Advanced computer numerical control (CNC) machines are often used in this stage to ensure high accuracy and consistency.

swing check valve factory

4. Assembly Once the individual components are manufactured, they are assembled to form the complete swing check valve. This includes installing the swinging disc, which allows fluid flow in one direction while preventing backflow. Proper alignment and sealing are critical during assembly to ensure functionality and durability.

5. Testing and Quality Control After assembly, each valve undergoes rigorous testing to verify its performance under specified conditions. This includes pressure testing, leakage testing, and functional testing to ensure the valve operates correctly. Quality control procedures are crucial at this stage, as they ensure that any defects are identified and rectified before the product reaches the market.

6. Finishing Once testing is complete, the valves undergo surface finishing to enhance corrosion resistance and aesthetic appeal. Processes may include painting, coating, or polishing, depending on the application requirements.

7. Packaging and Shipping Finally, fully assembled and tested valves are packaged for shipping. Factories ensure that the packaging is robust enough to protect the valves during transportation.

Innovation and Sustainability

As industries evolve, so do the technologies and practices within swing check valve factories. Innovations such as automation, advanced materials, and eco-friendly manufacturing processes are becoming more prevalent. Factories are increasingly focusing on sustainability, utilizing recyclable materials and reducing waste during production.

Conclusion

Swing check valve factories play an essential role in the production of reliable, efficient, and high-quality valves used across various industries. By understanding the intricate manufacturing processes and the importance of these valves, stakeholders can appreciate the complexities involved in ensuring that fluid systems operate smoothly and safely. As technology continues to advance, the future of swing check valve manufacturing looks promising, with a strong emphasis on innovation and sustainability.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025