ធ្នូ . 04, 2024 18:15 Back to list

stainless steel butterfly valve

Stainless Steel Butterfly Valves An Essential Component in Modern Piping Systems

In industrial applications, control over fluid flow is paramount, and one of the key components facilitating this is the butterfly valve. Among the various materials used in their construction, stainless steel has emerged as a preferred choice due to its enhanced durability, resistance to corrosion, and versatility. Stainless steel butterfly valves are integral components in numerous sectors, including water treatment, oil and gas, chemical processing, and HVAC systems.

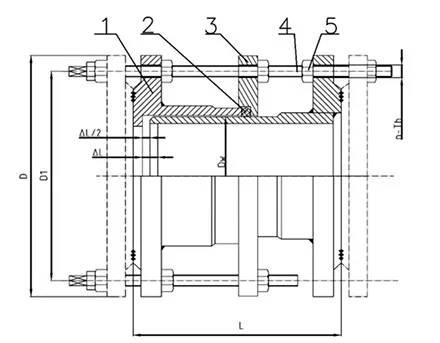

A butterfly valve operates by means of a rotating disc that pivots within the valve body. When the valve is closed, the disc sits perpendicular to the flow of the fluid, effectively blocking it. Conversely, when the valve is open, the disc rotates parallel to the flow, allowing fluid to pass through with minimal resistance. This simple yet effective mechanism provides rapid and efficient flow control, making butterfly valves suitable for a wide range of applications.

One of the most significant advantages of stainless steel butterfly valves is their resistance to corrosion. In many industries, fluids can be abrasive or contain chemicals that may degrade other materials. Stainless steel, specifically grades like 304 and 316, provides an excellent defense against such corrosive elements. Grade 316 stainless steel offers additional protection from chlorides and is often used in marine or chemical applications where high resistance to pitting and crevice corrosion is required.

The strength of stainless steel also plays a crucial role in the longevity and reliability of butterfly valves. Unlike plastic or some other metals, stainless steel maintains its structural integrity under high pressure and temperature conditions. This characteristic makes stainless steel butterfly valves capable of handling demanding environments, leading to reduced maintenance costs and extended service life.

stainless steel butterfly valve

Another advantage is the versatility of stainless steel butterfly valves

. They are available in various sizes and designs, including wafer, lug, and flanged types, making them suitable for different piping systems and configurations. Whether in a small-scale facility or a large industrial site, the adaptability of these valves allows for seamless integration into existing setups.Moreover, the ease of installation and maintenance of stainless steel butterfly valves further contributes to their popularity. Many models feature a lightweight design, allowing for simpler handling during installation. In terms of maintenance, the design of these valves often facilitates easy disassembly, enabling quick inspections and repairs when necessary.

The use of stainless steel butterfly valves also supports sustainability initiatives. Their durability reduces the need for frequent replacements, leading to less waste and lower overall environmental impact. Additionally, the efficiency of flow control provided by these valves can contribute to energy savings in systems that rely on fluid transport, aligning with the global movement towards more eco-friendly industrial practices.

In conclusion, stainless steel butterfly valves are an essential component in modern piping systems, offering numerous benefits such as corrosion resistance, strength, versatility, and ease of use. Their reliability in managing fluid flow in various industrial applications makes them an indispensable choice for engineers and operators alike. As industries continue to innovate and evolve, the demand for resilient and efficient flow control solutions like stainless steel butterfly valves is only expected to grow, reinforcing their critical role in the future of engineering and manufacturing.

Share