ធ្នូ . 05, 2024 15:32 Back to list

semi lugged butterfly valve

Understanding Semi-Lugged Butterfly Valves

In the realm of fluid control systems, the semi-lugged butterfly valve is an essential component that offers a unique blend of design efficiency, operational effectiveness, and durability. These valves are widely used in various industries, including water treatment, chemical processing, and HVAC (heating, ventilation, and air conditioning). This article explores the structure, functionality, advantages, and applications of semi-lugged butterfly valves.

Structure and Design

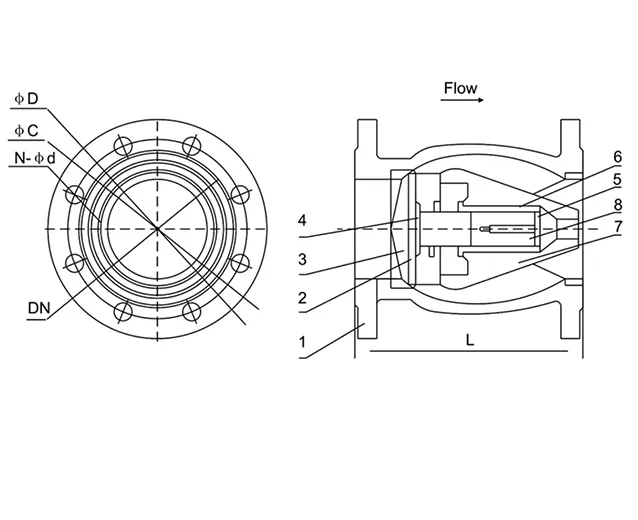

A semi-lugged butterfly valve is characterized by its disc-shaped closure element, which rotates around a shaft to either allow or restrict flow. Unlike fully lugged butterfly valves that feature threaded lugs extending from the valve body, semi-lugged valves possess a distinct design where lugs are only partially integrated. This provides a balance between strength and weight reduction.

The valve typically consists of the following main components

1. Body The body of the valve is often made from materials like cast iron, stainless steel, or PVC, depending on the operational environment and the nature of the fluid being controlled.

2. Disc The disc is the key component that modulates flow. It is positioned at the center of the valve and is designed to rotate with minimal friction. The shape of the disc is crucial, as it impacts the flow characteristics of the fluid passing through the valve.

3. Shaft The shaft connects the disc to the actuating mechanism, allowing for smooth rotation. The design of the shaft must accommodate the operational pressures and ensure longevity.

4. Seals To prevent leakage, semi-lugged butterfly valves are equipped with reliable sealing mechanisms, often made of elastomers or other resilient materials.

5. Actuator These valves can be operated manually or automatically via electric, pneumatic, or hydraulic actuators, allowing for varying levels of control and responsiveness.

Functionality

The primary function of a semi-lugged butterfly valve is to control the flow of fluids in a pipeline system. When the valve is fully open, the disc is parallel to the flow direction, allowing maximum fluid passage. Conversely, when closed, the disc obstructs the flow, creating a seal. The rotational movement of the disc is highly efficient, enabling rapid opening and closing, which is essential for processes requiring precise flow regulation.

Semi-lugged butterfly valves are particularly advantageous in applications where space is limited, as their design allows for compact installations. Their lightweight nature means reduced installation and handling costs, making them a preferred choice for many engineers and operators.

semi lugged butterfly valve

Advantages

The semi-lugged butterfly valve offers several notable advantages

1. Versatility They can handle a wide range of flow rates and fluid types, making them suitable for both industrial and commercial applications.

2. Low Pressure Drop The design of the valve minimizes flow resistance, contributing to a lower pressure drop across the valve compared to other types of valves, which can enhance system efficiency.

3. Cost-Effectiveness Reduced material usage due to its semi-lugged design often leads to lower production costs, making them an economical choice for large-scale operations.

4. Ease of Maintenance Semi-lugged butterfly valves allow for straightforward maintenance. The design facilitates easy access to internal components, enabling prompt servicing and repairs when necessary.

5. Durability Designed to withstand harsh operational conditions, these valves possess a long service life, ultimately reducing the need for frequent replacements.

Applications

Semi-lugged butterfly valves are utilized in various industries such as

- Water and Wastewater Treatment For regulating flow in treatment plants and distribution networks. - Chemical Processing For controlling corrosive and hazardous fluids in chemical plants. - HVAC Systems To manage air and fluid flows in heating and cooling systems. - Food and Beverage To handle sanitary applications while meeting stringent hygiene standards.

Conclusion

The semi-lugged butterfly valve represents a significant advancement in fluid control technology. With its unique design and versatile application potential, it stands out as a reliable solution for managing fluid flow in a myriad of industries. As technology continues to evolve, these valves will remain critical components in ensuring efficient and safe operations across various sectors. Understanding the characteristics and advantages of semi-lugged butterfly valves is essential for engineers and operators aiming to optimize their fluid handling systems.

Share

-

priming-a-pump-with-a-foot-valve-with-strainerNewsAug.23,2025

-

the-importance-of-a-y-strainer-in-pump-protectionNewsAug.23,2025

-

stainless-steel-ball-check-valve-for-high-purity-applicationsNewsAug.23,2025

-

common-applications-for-wafer-type-butterfly-valvesNewsAug.23,2025

-

seat-options-for-a-12-inch-knife-gate-valveNewsAug.23,2025

-

the-lifespan-of-a-typical-dismantling-jointNewsAug.23,2025