កុម្ភៈ . 14, 2025 21:49 Back to list

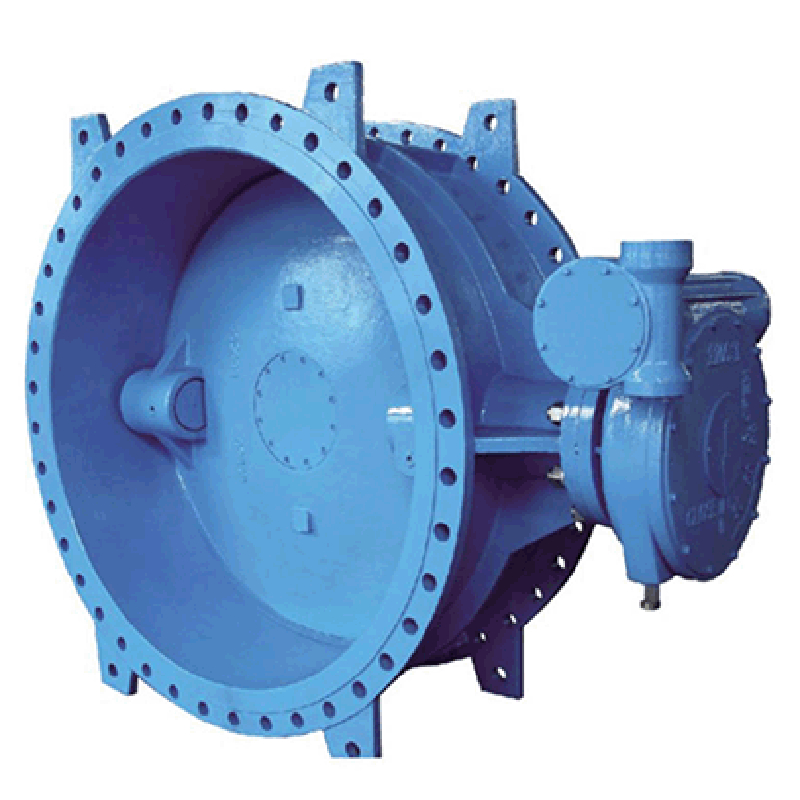

Socket End Resilient Gate valve

The knife gate valve pneumatic system is a specialized and reliable solution designed to handle challenging flow control scenarios in various industries. These valves are critical in sectors such as mining, wastewater treatment, and pulp and paper, where they manage the flow of thick fluids or media laden with solids. The distinct advantage of a knife gate valve lies in its ability to cut through these challenging materials, providing precise control and ensuring minimal downtime due to clogging.

Trustworthiness in knife gate valve pneumatic solutions is bolstered by rigorous testing and adherence to industry standards. Certified manufacturers guarantee that their products meet international standards such as ISO 9001 for quality management, instilling confidence in their clientele. Furthermore, customer testimonials often underscore the reliability and effectiveness of these systems in improving productivity and reducing unscheduled maintenance. For businesses evaluating knife gate valve pneumatic systems, cost-benefit analysis is advantageous. The initial investment is often offset by increased process efficiency and reduced downtime. Furthermore, advancements in technology have led to the integration of smart sensors, enabling predictive maintenance and real-time monitoring of valve performance. This innovation facilitates data-driven decision-making, crucial in maintaining a competitive edge in the industrial sector. In conclusion, knife gate valve pneumatic systems embody a synthesis of experience, expertise, authority, and trustworthiness. Their application is wide-ranging, addressing complex challenges in uniquely demanding environments. As industries evolve, staying informed about the latest advancements in valve technology and ensuring these tools are sourced from reputable suppliers will remain a pivotal aspect of maintaining efficient and productive operations.

Trustworthiness in knife gate valve pneumatic solutions is bolstered by rigorous testing and adherence to industry standards. Certified manufacturers guarantee that their products meet international standards such as ISO 9001 for quality management, instilling confidence in their clientele. Furthermore, customer testimonials often underscore the reliability and effectiveness of these systems in improving productivity and reducing unscheduled maintenance. For businesses evaluating knife gate valve pneumatic systems, cost-benefit analysis is advantageous. The initial investment is often offset by increased process efficiency and reduced downtime. Furthermore, advancements in technology have led to the integration of smart sensors, enabling predictive maintenance and real-time monitoring of valve performance. This innovation facilitates data-driven decision-making, crucial in maintaining a competitive edge in the industrial sector. In conclusion, knife gate valve pneumatic systems embody a synthesis of experience, expertise, authority, and trustworthiness. Their application is wide-ranging, addressing complex challenges in uniquely demanding environments. As industries evolve, staying informed about the latest advancements in valve technology and ensuring these tools are sourced from reputable suppliers will remain a pivotal aspect of maintaining efficient and productive operations.

Share