ធ្នូ . 31, 2024 00:16 Back to list

knife gate valve manufacturers

Understanding Knife Gate Valve Manufacturers A Comprehensive Overview

Knife gate valves are crucial components in various industrial applications, particularly where the handling of slurries, solids, and other thick fluids is required. These valves are designed to provide a reliable sealing mechanism that can withstand harsh operational conditions. As industries increasingly rely on efficient fluid management systems, the demand for high-quality knife gate valves has surged, resulting in a proliferation of manufacturers in this vital sector.

What is a Knife Gate Valve?

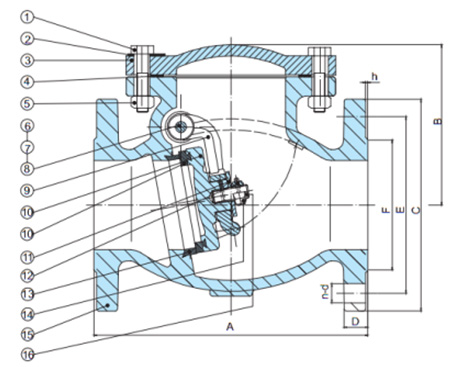

A knife gate valve is characterized by its simple design, which consists of a blade-like gate that slides between two sealing surfaces. This design allows it to cut through materials while providing a tight seal when closed. Knife gate valves are widely utilized in various industries, including wastewater treatment, mining, pulp and paper, and power generation. Their ability to effectively isolate flow, handle thick materials, and minimize maintenance makes them a popular choice among engineers and facility managers.

The Role of Manufacturers

Knife gate valve manufacturers play a pivotal role in ensuring the supply of reliable and durable valves. They typically focus on developing design innovations, adhering to industry standards, and employing high-quality materials. Most manufacturers offer a range of products tailored to different applications, providing options like manual, pneumatic, or electric actuation systems. They also focus on customization, where valves are designed according to specific client requirements and operational conditions.

Key Attributes of Knife Gate Valve Manufacturers

1. Quality Assurance Leading manufacturers implement rigorous quality control processes to ensure that their products meet both domestic and international standards. They are often certified by organizations such as ISO (International Organization for Standardization), ensuring that the valves withstand performance and safety benchmarks.

2. Material Selection The choice of materials is critical in producing knife gate valves capable of enduring abrasive and corrosive environments. Manufacturers typically use high-strength stainless steel, carbon steel, or specialized alloys, providing durability and resistance to wear and tear.

knife gate valve manufacturers

3. Innovation and Technology With the increasing complexity of industrial processes, manufacturers invest in research and development to design innovative valve solutions. This includes the incorporation of advanced technologies such as automated actuation systems, remote monitoring capabilities, and state-of-the-art sealing mechanisms.

4. Customer Support Beyond manufacturing, reputable companies provide superior customer service, offering guidance on valve selection, installation, and maintenance. They may also offer training sessions for facility staff to ensure optimal valve functionality and longevity.

5. Global Outreach Many knife gate valve manufacturers operate on a global scale, catering to diverse markets. They provide solutions tailored to regional needs while adhering to local regulations and standards.

Choosing the Right Manufacturer

When selecting a knife gate valve manufacturer, several factors should be considered

- Reputation Opt for manufacturers with a proven track record of reliability and customer satisfaction. - Product Range Evaluate the diversity of products offered to ensure that suitable options exist for specific applications. - Technical Support Ensure that the manufacturer provides comprehensive technical support and consultation to assist in making informed decisions. - Customization Capabilities For unique operational requirements, find a manufacturer willing to customize designs.

Summary

As industries evolve and demands for efficient fluid management increase, the role of knife gate valve manufacturers becomes ever more significant. By providing innovative, high-quality, and durable products tailored to specific needs, these manufacturers ensure that industrial processes run smoothly while minimizing downtime and maintenance costs. In a world where operational efficiency is paramount, investing in high-quality knife gate valves from reputable manufacturers is not just advantageous; it is essential for achieving long-term success. Whether for municipal applications or heavy industrial processes, the right knife gate valve can make a substantial difference in operational performance.

Share