មករា . 13, 2025 11:09 Back to list

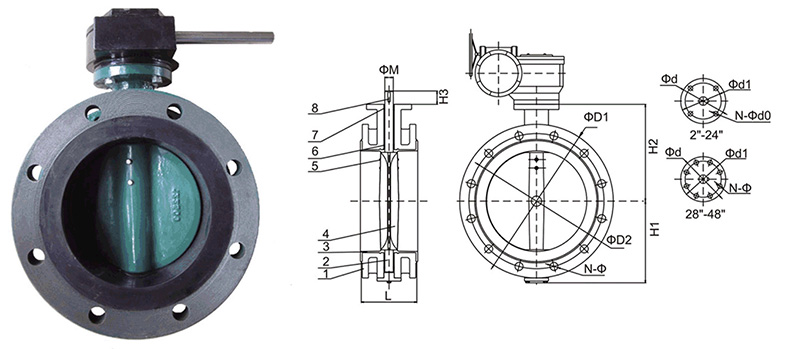

flange type butterfly valve

The importance of air valves in various industrial and commercial applications cannot be overstated. As crucial components, DI air valves—short for Ductile Iron air valves—play a pivotal role in maintaining the efficiency and reliability of fluid distribution systems. With a blend of robustness and precision engineering, DI air valves are engineered to serve a wide array of functionalities, ensuring optimal system performance and safeguarding against potential failures.

From an expert's perspective, choosing DI air valves also translates into cost-effectiveness. Their resilience reduces the need for frequent maintenance or replacements, significantly cutting long-term operational costs. Moreover, the ease of installation and maintenance due to their straightforward design adds another layer of economic advantage. For industries looking to bolster their operational reliability while managing expenditures, DI air valves emerge as an intelligent choice. Trust in DI air valves is embodied through their compliance with global quality and safety standards. These valves are subjected to rigorous testing through every stage of production, assuring stakeholders of their robustness and reliability. Manufacturers often back their products with certifications from prestigious organizations, reinforcing their commitment to delivering high-quality solutions. Such endorsements not only speak to the credibility of the valves but also instill confidence among engineers and purchasing managers alike. In conclusion, DI air valves occupy an authoritative position in the landscape of flow control systems. They harmonize durability with precision, offering invaluable benefits across diverse applications. By investing in DI air valves, industries can secure a physically resilient and economically sustainable future. As the complexities of industrial ecosystems continue to evolve, the necessity for components that exhibit unparalleled performance and trustworthiness becomes even more critical—a need that DI air valves comprehensively fulfill.

From an expert's perspective, choosing DI air valves also translates into cost-effectiveness. Their resilience reduces the need for frequent maintenance or replacements, significantly cutting long-term operational costs. Moreover, the ease of installation and maintenance due to their straightforward design adds another layer of economic advantage. For industries looking to bolster their operational reliability while managing expenditures, DI air valves emerge as an intelligent choice. Trust in DI air valves is embodied through their compliance with global quality and safety standards. These valves are subjected to rigorous testing through every stage of production, assuring stakeholders of their robustness and reliability. Manufacturers often back their products with certifications from prestigious organizations, reinforcing their commitment to delivering high-quality solutions. Such endorsements not only speak to the credibility of the valves but also instill confidence among engineers and purchasing managers alike. In conclusion, DI air valves occupy an authoritative position in the landscape of flow control systems. They harmonize durability with precision, offering invaluable benefits across diverse applications. By investing in DI air valves, industries can secure a physically resilient and economically sustainable future. As the complexities of industrial ecosystems continue to evolve, the necessity for components that exhibit unparalleled performance and trustworthiness becomes even more critical—a need that DI air valves comprehensively fulfill.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025