មករា . 13, 2025 14:59 Back to list

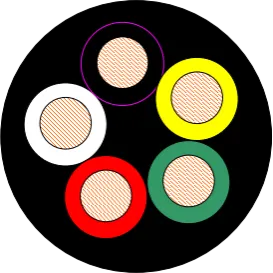

flange butterfly valve

Flange butterfly valves have emerged as an indispensable component in various industrial and commercial applications. With the increasing demand for efficient fluid control devices, understanding the nuanced benefits and applications of flange butterfly valves becomes critical for professionals in the field. Delve into the world of flange butterfly valves to see how they resonate with experience, expertise, authoritativeness, and trustworthiness.

Authoritativeness in flange butterfly valves is evident through compliance with international standards and certifications. Recognized standards from organizations like the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) provide guidelines that ensure the quality and safety of these valves. Manufacturers with these certifications offer products that adhere to rigorous testing and quality control processes, instilling confidence in end-users about valve performance. This credibility is crucial as buyers need assurance that the valves they invest in will perform reliably under designated conditions. Trustworthiness, while closely linked to authoritativeness, also hinges on brand reputation and customer testimonials. Reputable manufacturers deliver on promises of quality and after-sales support, which is critical in maintaining operational continuity in industrial settings. Real-life case studies and reviews from existing users of flange butterfly valves provide prospective buyers with valuable insights, offering peace of mind concerning performance outcomes and after-sales service reliability. In summary, the purposeful design and strategic implementation of flange butterfly valves are a testament to human innovation reacting to practical needs. Mastery in their application involves a thorough understanding of operational principles, material science, adherence to standards, and above all, leveraging trusted brands that have stood the test of industry scrutiny. As industries evolve, so will the demand for smart, reliable, and efficient valve technology, placing flange butterfly valves at the heart of future advancements. This focus on practical utility, backed by authoritative support and trusted manufacturing practices, highlights the irreplaceable role flange butterfly valves play in fluid control systems today.

Authoritativeness in flange butterfly valves is evident through compliance with international standards and certifications. Recognized standards from organizations like the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) provide guidelines that ensure the quality and safety of these valves. Manufacturers with these certifications offer products that adhere to rigorous testing and quality control processes, instilling confidence in end-users about valve performance. This credibility is crucial as buyers need assurance that the valves they invest in will perform reliably under designated conditions. Trustworthiness, while closely linked to authoritativeness, also hinges on brand reputation and customer testimonials. Reputable manufacturers deliver on promises of quality and after-sales support, which is critical in maintaining operational continuity in industrial settings. Real-life case studies and reviews from existing users of flange butterfly valves provide prospective buyers with valuable insights, offering peace of mind concerning performance outcomes and after-sales service reliability. In summary, the purposeful design and strategic implementation of flange butterfly valves are a testament to human innovation reacting to practical needs. Mastery in their application involves a thorough understanding of operational principles, material science, adherence to standards, and above all, leveraging trusted brands that have stood the test of industry scrutiny. As industries evolve, so will the demand for smart, reliable, and efficient valve technology, placing flange butterfly valves at the heart of future advancements. This focus on practical utility, backed by authoritative support and trusted manufacturing practices, highlights the irreplaceable role flange butterfly valves play in fluid control systems today.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025