ធ្នូ . 20, 2024 02:38 Back to list

ductile iron dismantling joint

Ductile Iron Dismantling Joints An Overview

Ductile iron dismantling joints are critical components in modern piping systems, particularly in water supply, wastewater management, and industrial applications. These joints provide the necessary flexibility and strength for effective maintenance and installation of pipelines, minimizing the potential for equipment failure and ensuring long-term durability. This article explores the characteristics, advantages, applications, and installation considerations of ductile iron dismantling joints.

Characteristics of Ductile Iron Dismantling Joints

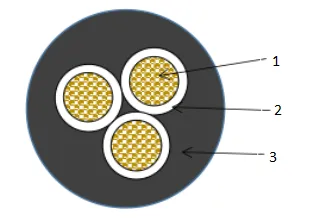

Ductile iron is an alloy that exhibits superior strength, ductility, and resistance to wear compared to traditional cast iron. Ductile iron dismantling joints are specifically designed to allow for easy disassembly of pipeline sections without the need for cutting or welding. The joint typically consists of two bell-shaped ends with flanges, connecting pipes or fittings. The key characteristics include

1. Flexibility Dismantling joints can accommodate slight misalignments and movements, reducing stress on the connected pipes. 2. Corrosion Resistance The surface of ductile iron joints is often coated with protective layers, enhancing resistance to corrosion and extending the lifespan of the joint. 3. Load-Bearing Capacity Ductile iron possesses a high tensile and yield strength, allowing dismantling joints to withstand significant pressure and loads in various applications. 4. Ease of Maintenance The design of dismantling joints simplifies maintenance procedures, facilitating quick access to pipeline sections for repairs or upgrades.

Advantages of Ductile Iron Dismantling Joints

The use of ductile iron dismantling joints offers several advantages over conventional piping methods

1. Reduced Installation Time The straightforward design of dismantling joints allows for quicker installation, reducing labor costs and project timelines. 2. Minimized Downtime In case of repairs or replacements, dismantling joints allow for rapid disassembly of sections, leading to less downtime in service continuity. 3. Flexible Design Options Different configurations and sizes of dismantling joints are available, making them suitable for a variety of applications ranging from residential plumbing to large-scale industrial systems. 4. Economical Although the initial investment in ductile iron dismantling joints may be higher than other materials, the long-term savings on maintenance and replacement costs often make them more cost-effective.

ductile iron dismantling joint

Applications of Ductile Iron Dismantling Joints

Ductile iron dismantling joints are utilized in numerous applications across different industries

1. Water and Wastewater Treatment These joints facilitate the maintenance of potable water systems and sewage networks by allowing for easy access to various pipeline sections for inspection and repairs. 2. Industrial Processes In manufacturing plants, dismantling joints assist in managing complex piping systems that require routine maintenance and adjustments, ensuring operational efficiency. 3. Fire Protection Systems Dismantling joints can be employed in fire protection systems, allowing for quick access to sections of pipelines during routine checks or in the event of an emergency.

Installation Considerations

Proper installation of ductile iron dismantling joints is crucial to ensuring their functionality and longevity. Key considerations include

1. Alignment It is vital to ensure that the pipes being connected are properly aligned to avoid undue stress on the joint. Proper alignment prevents potential leaks and enhances joint performance. 2. Torque Specifications Following manufacturer specifications for torque during installation is crucial. Over-tightening can lead to damage, while under-tightening may result in leaks. 3. Supports and Hangers Adequate supports and hangers should be installed to provide stability and prevent excessive movement of the pipes, which could compromise the integrity of the joint. 4. Inspection Regular inspections and maintenance of the dismantling joints will help identify wear, corrosion, or any issues that may arise, extending the life of the system.

Conclusion

Ductile iron dismantling joints serve as a cornerstone in modern piping systems, offering enhanced flexibility, strength, and ease of maintenance. Their advantages make them a popular choice across various industries, ensuring efficient operations while allowing for convenient access to pipeline systems. Understanding their characteristics, applications, and installation best practices is essential for engineers and maintenance professionals, ultimately contributing to the reliability and longevity of crucial infrastructure.

Share