ធ្នូ . 11, 2024 17:44 Back to list

Flexible Double Sphere Rubber Joint with Flange for Pipe Connections and Vibration Control

Double Sphere Flange Type Rubber Joint An Essential Component in Fluid Transportation

In the world of fluid transportation, maintaining efficiency and reliability is paramount. One key component that plays a crucial role in this domain is the double sphere flange type rubber joint. This specialized joint offers a range of benefits, particularly in systems involving piping and conveyor mechanisms. Understanding its structure, function, and advantages can help professionals in various industries optimize their operations.

Structure and Design

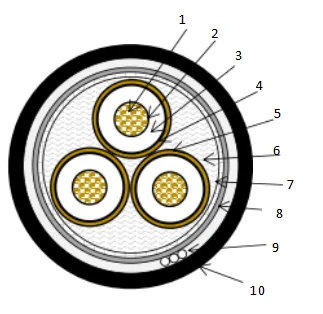

The double sphere flange type rubber joint, often referred to simply as a rubber joint, is characterized by its unique design that features two spherical ends connected by a flexible rubber body. The flanged ends facilitate easy installation and secure connections to piping systems. Typically constructed from high-quality elastomeric materials, the rubber body is designed to withstand significant pressure and accommodate movement caused by vibration and thermal expansion.

Rubber joints come with different flange specifications to match various piping standards, ensuring compatibility with existing systems. The use of high-grade rubber compounds contributes to exceptional durability and resistance against various environmental factors such as ozone, weather, and abrasion.

Functionality

One of the primary functions of the double sphere flange type rubber joint is to absorb vibrations and shock loads that occur in fluid transport systems. When fluids flow through pipes, they can create pressure fluctuations and vibrations that may lead to structural damage over time. The rubber joint acts as a damper, minimizing these vibrations and protecting the integrity of the entire system.

Additionally, the flexible nature of the rubber joint allows for angular displacements in the piping system. This capability is critical when dealing with misalignments caused by thermal expansion or settling of structures. By accommodating these movements, the rubber joint helps to prevent undue stress on pipes and fittings, significantly extending the lifespan of the infrastructure.

double sphere flange type rubber joint

Advantages

The benefits of utilizing double sphere flange type rubber joints are numerous. Firstly, their ability to absorb vibrations effectively not only increases the longevity of the piping system but also enhances the performance of pumps and other machinery connected to the system. Reduced wear and tear translate to lower maintenance costs and less downtime, which is invaluable in both industrial and municipal applications.

Moreover, these joints provide a degree of chemical resistance, making them suitable for a variety of fluids, including water, oils, and chemicals. Depending on the rubber compound used, they can be tailored for specific applications, ensuring compatibility and longevity.

Another significant advantage is ease of installation. The flanged design allows for quick and straightforward connections, reducing labor time and resource expenses during installation. This feature is particularly beneficial in emergency repairs where timely solutions are critical.

Applications

Double sphere flange type rubber joints are widely used across multiple sectors, including water treatment, HVAC systems, chemical processing, and power generation. Their versatile nature makes them applicable in both residential and industrial settings. From municipal water supply systems to large-scale manufacturing plants, these joints help ensure effective and reliable fluid transfer.

In conclusion, the double sphere flange type rubber joint is an indispensable component in modern fluid transportation systems. Its unique design, coupled with the ability to mitigate vibrations, accommodate misalignments, and resist various environmental factors, makes it vital for maintaining efficient operations. As industries continue to evolve, the reliance on such innovative components will only increase, affirming the importance of the rubber joint in ensuring safety, durability, and overall operational excellence.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025