ធ្នូ . 01, 2024 22:45 Back to list

Double Offset Flanged Butterfly Valve Design and Applications for Efficient Flow Control

Understanding Double Eccentric Flange Butterfly Valves

Butterfly valves are crucial components in various industrial applications, serving as flow control devices that regulate the passage of fluids in pipelines. Among the different types of butterfly valves available, the double eccentric flange butterfly valve stands out due to its unique design and operational advantages. This article will delve into the characteristics, functionalities, applications, and advantages of double eccentric flange butterfly valves, providing comprehensive insights for engineers and industry professionals.

What is a Double Eccentric Flange Butterfly Valve?

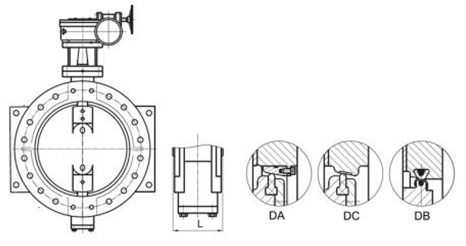

The double eccentric flange butterfly valve, also known as a high-performance butterfly valve, features a design where the shaft is positioned eccentrically relative to the valve seat and the butterfly disc. This geometry allows the valve to achieve higher efficiency in sealing and flow performance compared to traditional concentric designs. The term flange refers to the way the valve is connected to the pipeline, using flanged ends that secure the valve to the associated piping system.

Key Features

1. Eccentric Design The double eccentric design means that the disc of the valve does not rotate around the center point, but rather, it is displaced along the vertical and horizontal axes. This curvature leads to a tighter seal when the valve is closed, reducing wear on the sealing surfaces and minimizing leakage.

2. Sealing Performance The sealing performance of the double eccentric flange butterfly valve is significantly improved due to the design. As the valve closes, the disc moves away from the seat, which allows a smooth and gradual compression of the sealing material, leading to less stress and longer lifespan.

3. Lightweight and Compact These valves are typically lighter and take up less space compared to other types of valve designs, such as gate or globe valves. This feature makes installation and maintenance easier, especially in space-constrained environments.

Applications

double eccentric flange butterfly valve

The applications of double eccentric flange butterfly valves are diverse, reflecting their adaptability

- Water Supply Systems They are widely used in municipal water treatment plants for regulating water flow and preventing backflow. - Chemical Industry In chemical processing, these valves control the flow of corrosive and non-corrosive liquids, demonstrating excellent chemical resistance. - Gas Distribution In the gas industry, these valves ensure secure and efficient flow regulation, maintaining safety in operations. - HVAC Systems In heating, ventilation, and air-conditioning systems, they contribute to energy efficiency by regulating airflow.

Advantages

1. Reduced Torque Requirements The eccentric design significantly reduces the torque needed to operate the valve, resulting in lower power consumption and extending the life of the actuator.

2. Enhanced Flow Characteristics The streamlined flow path ensures minimal resistance, thus optimizing hydraulic performance both when the valve is fully open and during throttling conditions.

3. Improved Durability The reduction in wear and tear due to less direct contact between the sealing surfaces leads to extended service life, making it an economical choice in the long run.

4. Maintenance-Friendly The design allows for easy access for maintenance and repairs, as the valve can often be serviced without needing to be removed from the pipeline.

Conclusion

In conclusion, the double eccentric flange butterfly valve represents a sophisticated solution for flow control in various industrial applications. Its unique design offers distinct advantages such as improved sealing performance, reduced torque requirements, and increased durability, making it an ideal choice for engineers and facility managers. As industries continue to seek efficient and reliable solutions for fluid management, double eccentric flange butterfly valves will undeniably play a pivotal role in enhancing operational efficiency and sustainability. Whether in water treatment, chemical processing, or gas distribution, their versatility and design excellence will drive their popularity well into the future.

Share

-

Y Strainers: Protecting Your Pipes with PrecisionNewsAug.27,2025

-

Wafer Type Butterfly Valves: Reliable Flow Control SolutionsNewsAug.27,2025

-

Wafer Type Butterfly Valves: Essential Components for Efficient Flow ControlNewsAug.27,2025

-

Reliable Flow Control with High-Quality Check ValvesNewsAug.27,2025

-

Reliable Flow Control with Gate ValvesNewsAug.27,2025

-

Innovative Check Valves for Reliable Flow ControlNewsAug.27,2025