កុម្ភៈ . 08, 2025 05:28 Back to list

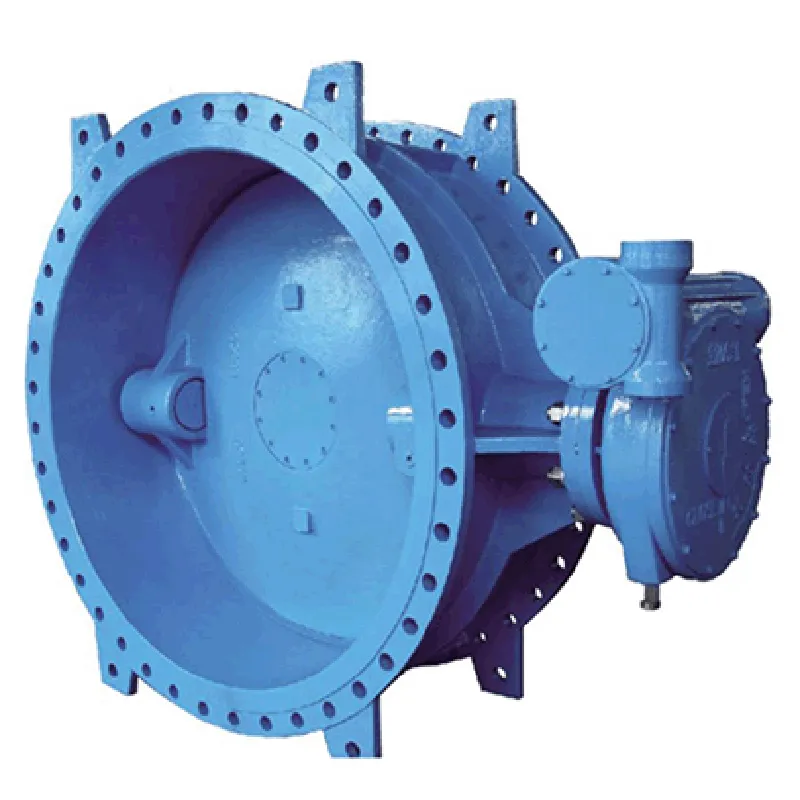

ball type check valve

The cast steel check valve is an essential component in various industrial pipelines, known for its resilience and efficiency in preventing backflow. In manufacturing and processing sectors, where fluid control is paramount, this valve type stands out due to its robust construction and reliability. Here, we delve into the experience of using cast steel check valves, their technical expertise, authoritative presence in the market, and the trust they command among industry professionals.

Trustworthiness in cast steel check valves is reinforced by the transparency with which manufacturers share technical data and performance metrics. Detailed product sheets, case studies, and third-party test results are often available to potential buyers, allowing them to make informed decisions. The long service life and low failure rates of these valves further cement their reputation as dependable components in critical infrastructure. Customers often report that the initial investment in high-quality cast steel check valves pays off through reduced downtime and increased operational efficiency. In addition to their primary function of preventing backflow, cast steel check valves bring added value through their adaptability and customization options. Manufacturers offer a range of sizes, pressure ratings, and end connections, including flanged, threaded, and welded options. These variations allow for precise matching with specific application requirements, ensuring optimal performance. Some manufacturers also provide bespoke solutions to address unique challenges in fluid systems, such as specialized coatings or temperature-resilient materials. In conclusion, the adoption of cast steel check valves is a testament to their proven track record in challenging environments. Engineers and plant managers favor them for their durability, precision engineering, and adaptability. By prioritizing experience, expertise, authority, and trust, these valves consistently deliver performance that meets industry demands, making them an indispensable component in the vast landscape of fluid control systems. Whether in a state-of-the-art refinery or a wastewater treatment plant, the cast steel check valve remains a cornerstone of efficient and reliable operation.

Trustworthiness in cast steel check valves is reinforced by the transparency with which manufacturers share technical data and performance metrics. Detailed product sheets, case studies, and third-party test results are often available to potential buyers, allowing them to make informed decisions. The long service life and low failure rates of these valves further cement their reputation as dependable components in critical infrastructure. Customers often report that the initial investment in high-quality cast steel check valves pays off through reduced downtime and increased operational efficiency. In addition to their primary function of preventing backflow, cast steel check valves bring added value through their adaptability and customization options. Manufacturers offer a range of sizes, pressure ratings, and end connections, including flanged, threaded, and welded options. These variations allow for precise matching with specific application requirements, ensuring optimal performance. Some manufacturers also provide bespoke solutions to address unique challenges in fluid systems, such as specialized coatings or temperature-resilient materials. In conclusion, the adoption of cast steel check valves is a testament to their proven track record in challenging environments. Engineers and plant managers favor them for their durability, precision engineering, and adaptability. By prioritizing experience, expertise, authority, and trust, these valves consistently deliver performance that meets industry demands, making them an indispensable component in the vast landscape of fluid control systems. Whether in a state-of-the-art refinery or a wastewater treatment plant, the cast steel check valve remains a cornerstone of efficient and reliable operation.

Share

Prev:

Next: