វិច្ឆិកា . 22, 2024 10:35 Back to list

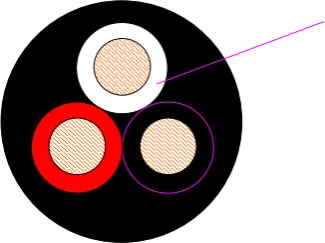

cast iron butterfly valve

Understanding Cast Iron Butterfly Valves Durability and Efficiency in Fluid Control

Butterfly valves are essential components in many industrial applications, providing a simple and effective method for controlling the flow of liquids and gases. Among the various materials used to manufacture these valves, cast iron is one of the most popular choices due to its durability and resistance to wear and tear. This article will explore the features, advantages, and applications of cast iron butterfly valves.

What is a Butterfly Valve?

A butterfly valve consists of a circular disk (the butterfly) that rotates on a shaft to open or close the valve. When the valve is fully open, the disk is parallel to the flow of the fluid, allowing minimal resistance; when closed, the disk is perpendicular to the flow, completely blocking it. This simple yet effective design makes butterfly valves an excellent choice for a wide range of applications, from water supply systems to industrial processes.

Benefits of Cast Iron Material

1. Durability Cast iron is known for its strength and durability, making it ideal for butterfly valves that must withstand high pressures and harsh operating conditions. Its ability to resist deformation under stress ensures a long service life, reducing the need for frequent replacements.

2. Corrosion Resistance While cast iron is not completely immune to corrosion, it can be treated and coated to enhance its resistance to rust and degradation. This characteristic is especially important in environments where valves are exposed to water, chemicals, or other corrosive substances.

3. Cost-Effective Compared to other materials such as stainless steel or bronze, cast iron is generally more affordable. This cost-effectiveness makes it an attractive option for various industrial applications, providing good performance without significantly impacting project budgets.

4. Thermal Conductivity Cast iron has excellent thermal conductivity, which can be beneficial in applications where temperature fluctuations are common. This property ensures that the valve can effectively handle hot fluids without compromising its integrity.

cast iron butterfly valve

Applications of Cast Iron Butterfly Valves

Cast iron butterfly valves are utilized in a wide range of industries, thanks to their versatility and reliability. Some common applications include

- Water Supply and Wastewater Treatment These valves are widely used in municipal water systems and sewage treatment plants to manage the flow of water and waste effectively.

- HVAC Systems In heating, ventilation, and air conditioning systems, cast iron butterfly valves help regulate the flow of air and fluids, contributing to overall system efficiency.

- Chemical Processing The ability to withstand corrosive substances makes cast iron butterfly valves suitable for handling various chemicals in the manufacturing sector.

- Power Generation In power plants, these valves are essential for regulating steam and cooling water flows, ensuring efficient operation and safety.

Conclusion

In summary, cast iron butterfly valves are a vital component in multiple industries, offering durability, corrosion resistance, and cost savings. Their simple design allows for efficient flow control, making them an ideal choice for a variety of applications. As industries continue to evolve, the demand for reliable and effective flow control solutions will undoubtedly keep cast iron butterfly valves at the forefront of fluid management technology. Whether in water treatment facilities, HVAC systems, or chemical processing plants, these valves play a critical role in ensuring operational efficiency and safety.

Share