តុលា . 07, 2024 08:06 Back to list

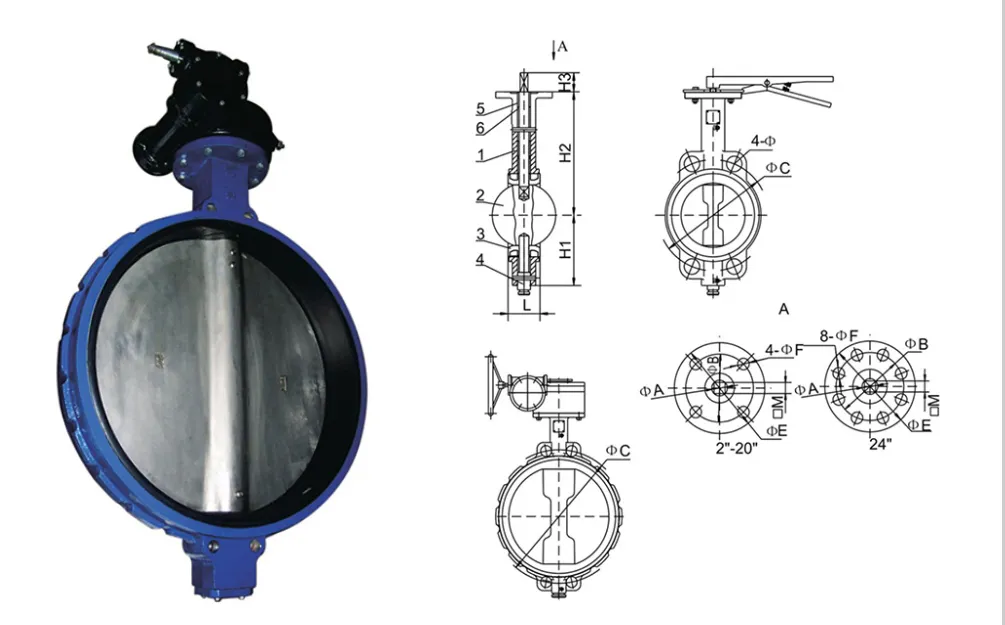

actuated valve

The Role of Actuated Valves in Modern Automation

In the realm of industrial automation, actuated valves play a crucial role in the seamless operation of numerous systems. These devices are integral components in various applications, ranging from water treatment to oil and gas processing. Understanding the functioning, benefits, and applications of actuated valves can significantly enhance operational efficiency and reliability.

An actuated valve is essentially a valve that is controlled by an external mechanism, often referred to as an actuator. The actuator may be powered by electric, pneumatic, or hydraulic energy. This automated control allows for precise regulation of fluid flow, enabling operations to be conducted with minimal human intervention. The ability to automate valve operation has transformed many industrial processes, allowing for greater accuracy and speed.

One of the primary functions of an actuated valve is to open or close the flow of fluids in a system

. This capability is critical in maintaining safety and efficiency, especially in high-stakes environments such as chemical manufacturing or power generation. By automating valve operation, industries can minimize the risk of human error, which is often a factor in accidents and inefficiencies. Moreover, actuated valves can be integrated into larger control systems, enabling real-time monitoring and adjustments to fluid flow as needed.actuated valve

There are various types of actuated valves, each suited for specific applications. For instance, electric actuators are commonly used in scenarios requiring precise positioning and rapid response times. Pneumatic actuators, on the other hand, are favored for their ability to deliver quick movements and high force, making them ideal for high-pressure systems. Hydraulic actuators can handle even more substantial loads, providing an effective solution for heavy-duty applications.

The benefits of employing actuated valves extend beyond operational efficiency. Incorporating these valves into industrial systems can lead to significant cost savings. With increased automation, companies can reduce labor costs and enhance productivity. Furthermore, actuated valves contribute to energy savings by optimizing fluid dynamics in a system, which reduces the need for excessive pumping or heating.

Additionally, actuated valves are designed with safety features that can further mitigate risks associated with fluid handling. Many systems include fail-safe mechanisms that ensure valves revert to a safe position in the event of a power failure, thereby preventing potential spills or leaks. This added layer of security is particularly important in industries dealing with hazardous materials.

In conclusion, actuated valves represent a pivotal advancement in industrial automation. Their ability to enhance control over fluid systems not only boosts operational efficiency but also significantly impacts safety and cost-effectiveness. As industries continue to evolve and adopt more automated solutions, the importance of actuated valves will only grow. Going forward, investing in this technology will prove essential for companies aiming to stay competitive in an increasingly automated world.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025