ធ្នូ . 11, 2024 19:36 Back to list

6-inch Ball Valve Specifications and Applications for Fluid Control Systems

Understanding the 6-Inch Ball Valve Functionality and Applications

The 6-inch ball valve is a critical component in many industrial and commercial fluid control systems. Renowned for its simplicity, durability, and efficiency, this valve type plays a significant role in regulating the flow of liquids and gases in various applications. In this article, we will delve into the design, functionality, and common uses of 6-inch ball valves, illuminating their importance in the fluid dynamics landscape.

The Design of a 6-Inch Ball Valve

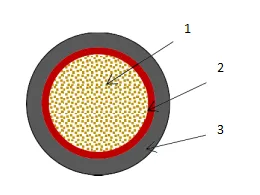

The 6-inch ball valve is characterized by its spherical disc, known as the ball, which has a hollow center. This design allows for effective isolation of flow with minimal pressure drop. The size, indicated by the 6-inch designation, refers to the diameter of the valve’s bore. Typically, the valve body is constructed from robust materials such as stainless steel, brass, or carbon steel to withstand varying pressure and temperature conditions. Additionally, the valve usually features a handle or actuator mechanism for ease of operation. Some models might include extended necks or flanged connections for better alignment and installation.

Working Mechanism

The operational principle of a ball valve is straightforward. When the handle is turned 90 degrees, the ball rotates, and the flow is either allowed or blocked. In the open position, the ball’s hole aligns with the pipe, permitting fluid flow. In stark contrast, in the closed position, the solid part of the ball blocks the path, effectively stopping any flow. This quick on/off functionality makes ball valves highly efficient for applications requiring rapid shutoff or flow control.

One of the distinguishing features of 6-inch ball valves is their ability to handle a wide range of media. From water and oil to chemicals and gas, their robust construction allows them to function effectively in diverse environments, including high-pressure and high-temperature applications.

Advantages of 6-Inch Ball Valves

1. Quick Operation The 90-degree rotation feature offers rapid opening and closing, making it ideal for emergency shutoff situations.

3. High Durability With proper maintenance, a high-quality ball valve can last for decades, even under challenging operating conditions.

6 inch ball valve

4. Versatility Suitable for a plethora of applications, 6-inch ball valves can be utilized in water treatment plants, oil and gas pipelines, chemical manufacturing, and HVAC systems.

5. Low Maintenance The design minimizes the need for frequent repairs or replacements, making it a cost-effective choice over time.

Common Applications

6-inch ball valves find extensive use across various industries

- Water Supply Systems In municipal water systems, these valves are used for controlling water flow to different areas, ensuring consistent supply and pressure.

- Oil and Gas The oil and gas industry utilizes ball valves to manage the flow of crude oil, natural gas, and refined products. Their ability to withstand high pressures is essential in this sector.

- Chemical Processing The chemical industry relies on ball valves to handle corrosive liquids and gases, thanks to available materials resistant to chemical degradation.

- HVAC Systems In heating, ventilation, and air conditioning systems, these valves help regulate air and fluid flow, contributing to energy efficiency and system control.

Conclusion

The 6-inch ball valve serves as a quintessential tool in modern engineering and industrial operations. Its robust design, ease of operation, and versatility make it indispensable across various sectors. Whether managing volatile oil and gas flows or essential water supply systems, the ball valve's dependable performance ensures smooth and efficient process management. As industries advance toward more sophisticated technologies, the fundamental role of reliable components like the 6-inch ball valve will undoubtedly continue to be pivotal in shaping efficient fluid control systems across the globe.

Share