វិច្ឆិកា . 14, 2024 15:36 Back to list

4 way ball valve

Understanding the 4-Way Ball Valve A Versatile Solution for Fluid Control

In various industrial applications, the need for efficient fluid control is paramount. Among the numerous types of valves available, the 4-way ball valve stands out for its versatility and effectiveness. This valve type is designed to manage the flow of fluids in multiple directions, making it an essential component in many piping systems.

What is a 4-Way Ball Valve?

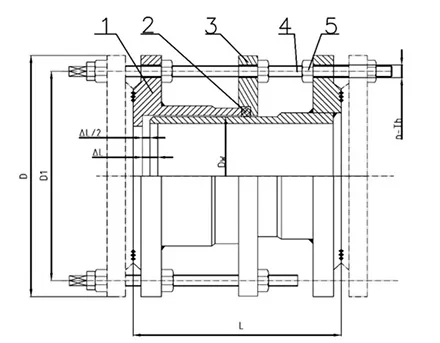

A 4-way ball valve is a type of valve that includes a spherical disc with four ports, allowing for the fluid flow to be diverted in multiple directions. The valve body typically has a ball with either two or four openings. The ball is rotated 90 degrees to open or close the ports, thus controlling the flow path. Depending on the configuration, these valves can either direct fluid to two outputs simultaneously or selectively isolate specific lines.

Applications of 4-Way Ball Valves

The versatility of 4-way ball valves makes them suitable for various applications across different industries. One common usage is in heating, ventilation, and air conditioning (HVAC) systems, where they can transfer fluid between two heating or cooling sources. In chemical processing, they are employed to redirect fluids between reactors and storage systems, enhancing overall process efficiency.

In hydraulic systems, these valves are instrumental in controlling the direction of flow within circuitries. This control is vital for achieving desired movements in hydraulic machinery. Furthermore, in oil and gas industries, 4-way ball valves are used to manage crude oil and gas flow, ensuring safe and efficient operation under high pressures.

Advantages of 4-Way Ball Valves

4 way ball valve

One of the primary advantages of 4-way ball valves is their ability to provide multiple flow paths without the need for additional piping or valves. This not only saves space but also reduces installation costs and complexity. Additionally, 4-way ball valves offer a tight sealing capability, which minimizes leakage and enhances safety in high-pressure applications.

These valves also exhibit quick operation; the 90-degree turn of the valve provides rapid opening and closing, making them suitable for systems requiring fast response times. The robust design of ball valves ensures they can withstand high pressures and temperatures, further increasing their reliability in demanding environments.

Considerations When Choosing a 4-Way Ball Valve

When selecting a 4-way ball valve for your application, several factors must be considered. The type of fluid being handled, the temperature and pressure conditions, and the required flow rate are all critical aspects. Additionally, the valve material must be compatible with the fluid to prevent corrosion or degradation.

Another important consideration is the valve’s actuation method. Manual, pneumatic, and electric actuators are all viable options, depending on the automation requirements of your system. Ensuring that the actuation method aligns with operational needs will enhance the effectiveness of the valve in fluid control.

Conclusion

In conclusion, the 4-way ball valve is a versatile and efficient solution for managing fluid flow in a variety of industrial applications. Its ability to redirect fluid in multiple directions, combined with the advantages of a compact design and rapid operation, makes it an invaluable component in many engineering systems. Understanding its applications and advantages can help industries maximize their fluid control operations, contributing to increased safety and efficiency. As technology advances, the role of 4-way ball valves is likely to become increasingly significant in fluid management solutions.

Share