វិច្ឆិកា . 19, 2024 10:23 Back to list

12 inch butterfly valve specifications and applications for efficient flow control systems

Understanding the 12% 20-Inch Butterfly Valve A Key Component in Fluid Control

Butterfly valves play a crucial role in controlling the flow of fluids in various industrial applications. Among the different types of butterfly valves, the 12% 20-inch butterfly valve stands out due to its unique design and application capabilities. This article aims to provide an overview of this specific valve, its features, advantages, and applications in fluid dynamics.

What is a Butterfly Valve?

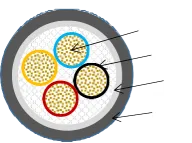

A butterfly valve is a type of quarter-turn valve that uses a rotating disc to regulate fluid flow. When the disc is rotated parallel to the flow direction, the valve opens, allowing fluid to pass through. Conversely, when the disc is rotated perpendicular to the flow, the valve closes, halting the fluid passage. Butterfly valves are recognized for their simple and compact design, making them ideal for various applications.

Features of the 12% 20-Inch Butterfly Valve

The designation of 12% 20-inch refers to the specific size and design parameters of the valve. The 20-inch denotes the nominal diameter of the valve, making it suitable for large-scale applications requiring significant fluid throughput. The 12% typically indicates the flow characteristic of the valve, specifically its capacity to achieve 12% flow variation for a given actuator movement. This feature is particularly useful in applications demanding precise flow control.

Additionally, the butterfly valve is designed with a disc that can pivot around a shaft, which is supported at the center of the body. This design allows for a minimization of pressure loss and a lightweight construction that reduces the overall system weight. Common materials used in the construction of these valves include ductile iron, stainless steel, and PVC, making them resistant to corrosion and suitable for various fluid types.

12 inch butterfly valve

Advantages of Using a 12% 20-Inch Butterfly Valve

One of the main advantages of using a 12% 20-inch butterfly valve is its efficiency in controlling flow. With a quick quarter-turn operation, it allows for rapid opening and closing, which can be critical in processes where fluid flow needs to be adjusted swiftly. Moreover, the design minimizes turbulence, reducing the risk of pressure drop across the valve, thereby enhancing system performance.

Additionally, these valves require less maintenance compared to other types of valves, such as gate or globe valves, due to their simple construction. Their compact design allows for easy installation in tight spaces and can be operated manually or automated for enhanced control.

Another significant advantage is the versatility of the 12% 20-inch butterfly valve. They are suitable for various applications, including water treatment plants, chemical processing, HVAC systems, and even in food processing industries. Their ability to handle different pressure levels and flow rates makes them a favorable choice for engineers and system designers.

Applications

In practice, the 12% 20-inch butterfly valve is widely used in scenarios where space is limited, and efficiency is paramount. They are commonly found in piping systems, where they manage the flow of water, chemicals, gases, and slurries. Additionally, they are instrumental in regulating system pressure and can be applied in both on-off and throttling services.

In summary, the 12% 20-inch butterfly valve emerges as a vital component in fluid control systems. Its efficient design, ease of maintenance, and versatility make it an invaluable tool across various industries, paving the way for improved operational performance in fluid management systems.

Share