Жел . 10, 2024 16:45 Back to list

CI Flanged Ball Valve Specifications and Applications for Industrial Use

Understanding CI Flanged Ball Valves A Comprehensive Overview

CI flanged ball valves are critical components widely used in various industrial applications due to their efficiency and reliability in controlling the flow of fluids. CI, or Cast Iron, is a material known for its durability and strength, making it an ideal choice for creating robust valves that can withstand high pressures and temperatures. This article explores what CI flanged ball valves are, their advantages, applications, and maintenance considerations.

What are CI Flanged Ball Valves?

A flanged ball valve is a type of valve that uses a spherical disc, known as a ball, to control the flow of fluid through it. The ball has a bore that allows fluid to pass through when aligned with the flow direction. When the ball is rotated 90 degrees, the flow is shut off. The term flanged refers to the design of the valve's ends, which have flanges that allow for easy connection to pipes using bolts. This feature simplifies installation and maintenance and provides a secure and leak-free seal.

Advantages of CI Flanged Ball Valves

1. Durability and Strength Cast iron is a strong material that can resist wear and tear, making CI flanged ball valves suitable for high-pressure and high-temperature applications. They are less prone to damage caused by corrosion, making them a reliable choice for many industries.

2. Versatility CI flanged ball valves can be used in various applications, including water supply systems, gas and oil transportation, chemical processing, and HVAC systems. Their ability to handle different fluids, including corrosive substances, makes them versatile in multiple environments.

3. Easy Operation These valves are designed for quick and easy operation. The simple quarter-turn mechanism allows for rapid opening and closing, ensuring that flow control can be achieved swiftly when necessary.

4. Leak-Proof Design The flanged connection provides a tight seal between the valve and the piping, reducing the risk of leaks. This feature is essential in industries where fluid loss can lead to safety hazards or financial losses.

5. Maintenance Friendly CI flanged ball valves require minimal maintenance compared to other valve types. Routine checks and occasional lubrication can keep them functioning effectively, providing long-term reliability and reducing downtime.

Applications of CI Flanged Ball Valves

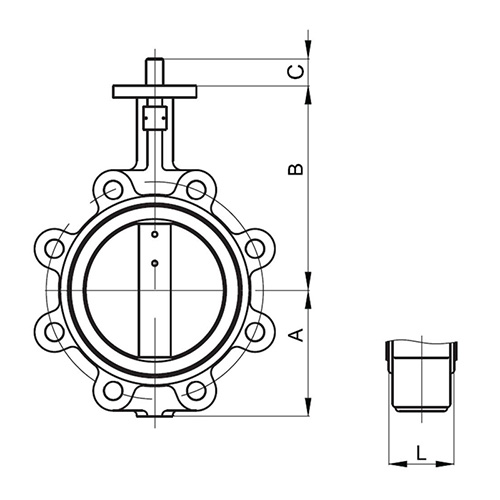

ci flanged ball valve

The applications of CI flanged ball valves are vast

. They are commonly used in- Water Treatment Plants For controlling the flow of water and chemicals used in purification processes. - Oil and Gas Industry To regulate the flow of crude oil and natural gas in pipelines and processing facilities. - Chemical Processing Where they manage the flow of various chemicals, ensuring safety and efficiency. - Heating, Ventilation, and Air Conditioning (HVAC) To control heating and cooling fluids in residential and commercial buildings. - Fire Protection Systems To control water flow in sprinkler systems and fire hoses.

Maintenance Considerations

While CI flanged ball valves are known for their durability, regular maintenance is essential to ensure their long-term performance. Here are some tips

1. Regular Inspection Periodically check the valve for any signs of wear, corrosion, or leakage. Early detection can prevent major issues and extend the valve's life.

2. Lubrication Keeping the valve’s moving parts lubricated will help in smooth operation and prevent seizing.

3. Sealing Inspection Ensure that the seals and gaskets are in good condition. If any degradation is observed, replace them promptly to avoid leaks.

4. Cleaning Regular cleaning to remove dirt and debris can help maintain optimal performance and prevent blockage in the flow path.

5. Operational Testing Conduct operational tests to ensure that the valve opens and closes smoothly without any obstructions.

Conclusion

CI flanged ball valves are essential for effective fluid control in various industries. Their durable construction, ease of use, and versatile applications make them a popular choice among engineers and facility managers. By understanding their advantages and following proper maintenance practices, businesses can ensure the reliability and efficiency of their fluid systems, achieving seamless operational performance. Whether in oil and gas, chemical processing, or water treatment, CI flanged ball valves play a pivotal role in enhancing workflow and maintaining safety standards.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025