Feb . 13, 2025 17:48 Back to list

Dual Plate Check Valve

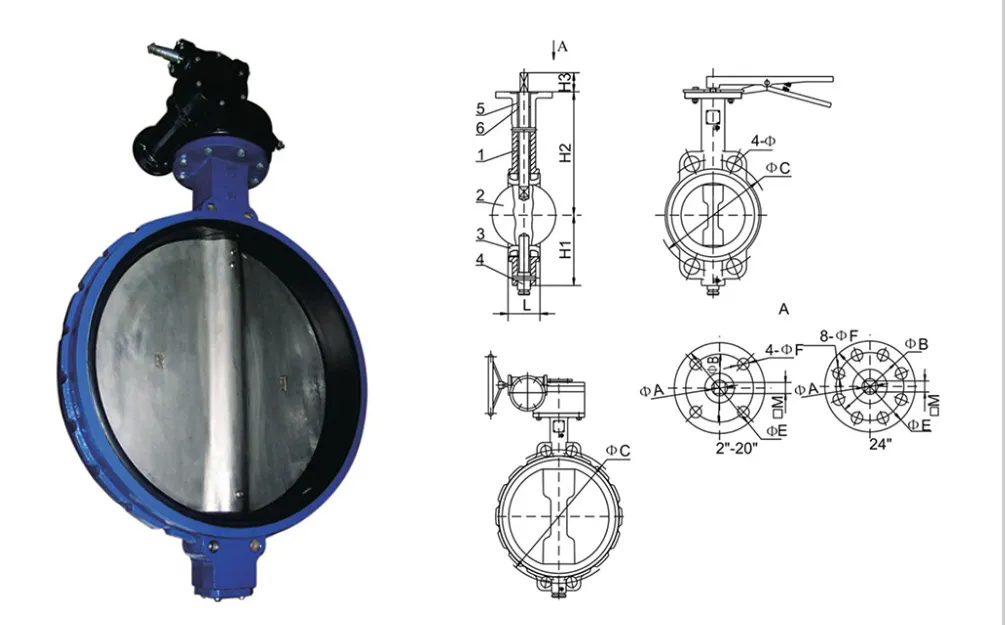

The wafer type butterfly check valve is an essential component in modern fluid control systems, known for its efficiency and durability. Its unique design combines a wafer body and a check valve mechanism, making it a top choice for engineers and procurement specialists seeking reliable solutions for their piping systems.

Understanding the specific requirements of your fluid system is vital when selecting a wafer type butterfly check valve. Factors such as fluid type, temperature, and pressure ratings must align with the valve's specifications to ensure optimal performance. Consulting with an expert in industrial valve solutions can provide invaluable insights, helping to select a valve that not only meets the current system demands but also offers flexibility for future scalability. Trustworthiness is crucial in this industry, and it begins with choosing a reputable manufacturer. Innovative valve manufacturers typically adhere to stringent quality control protocols, often surpassing international standards like API, ANSI, and ISO. Such certifications validate the product’s quality and performance, instilling confidence in buyers about their investment's reliability. Authoritative voices in the valve manufacturing sector acknowledge the wafer type butterfly check valve as a transformative solution, owing to its versatile applicability across varied industries. Case studies and real-world applications further validate its effectiveness, showcasing instances of robust performance in both standard and specialized applications. In conclusion, the wafer type butterfly check valve is not just a component but an integral part of modern fluid handling systems. Its expertise-driven design and proven reliability make it an indispensable choice for those seeking efficiency, durability, and seamless performance in fluid control. Investing in such a valve ensures a well-rounded solution that upholds industry standards and delivers consistent results under the most demanding conditions. Ensure you consult with valve experts to explore possibilities and tailor solutions that meet your specific needs.

Understanding the specific requirements of your fluid system is vital when selecting a wafer type butterfly check valve. Factors such as fluid type, temperature, and pressure ratings must align with the valve's specifications to ensure optimal performance. Consulting with an expert in industrial valve solutions can provide invaluable insights, helping to select a valve that not only meets the current system demands but also offers flexibility for future scalability. Trustworthiness is crucial in this industry, and it begins with choosing a reputable manufacturer. Innovative valve manufacturers typically adhere to stringent quality control protocols, often surpassing international standards like API, ANSI, and ISO. Such certifications validate the product’s quality and performance, instilling confidence in buyers about their investment's reliability. Authoritative voices in the valve manufacturing sector acknowledge the wafer type butterfly check valve as a transformative solution, owing to its versatile applicability across varied industries. Case studies and real-world applications further validate its effectiveness, showcasing instances of robust performance in both standard and specialized applications. In conclusion, the wafer type butterfly check valve is not just a component but an integral part of modern fluid handling systems. Its expertise-driven design and proven reliability make it an indispensable choice for those seeking efficiency, durability, and seamless performance in fluid control. Investing in such a valve ensures a well-rounded solution that upholds industry standards and delivers consistent results under the most demanding conditions. Ensure you consult with valve experts to explore possibilities and tailor solutions that meet your specific needs.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025