Dec . 20, 2024 05:37 Back to list

single plate check valve

Understanding Single Plate Check Valves

Check valves play a critical role in many industrial applications, ensuring that fluid flows in one direction while preventing backflow. Among various types of check valves, the single plate check valve stands out due to its unique design and efficiency. This article will delve into the structure, advantages, applications, and maintenance of single plate check valves.

Structure of Single Plate Check Valves

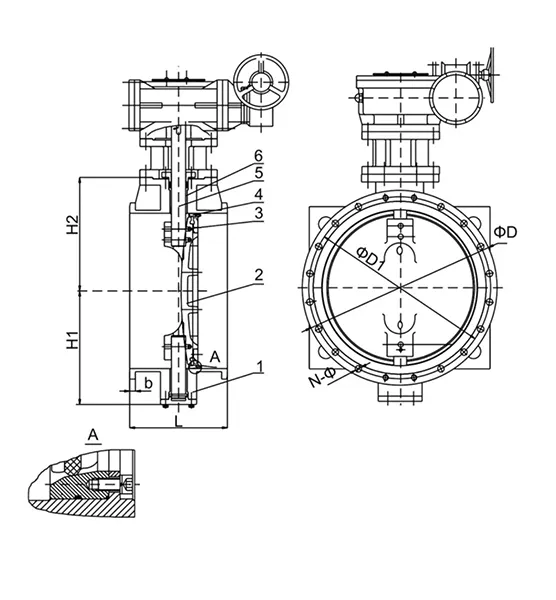

A single plate check valve, as the name suggests, consists of a single disc or plate that swings on a hinge. This construction allows the valve to open and close in response to pressure changes in the fluid system. When the fluid flow is in the correct direction, the pressure forces the disc to lift, allowing the fluid to pass through. Conversely, if there is a reverse flow or pressure drops, the disc swings back into a closed position, effectively preventing backflow.

The simplicity of the single plate mechanism is one of its major advantages. It typically has fewer moving parts compared to other types of check valves, such as dual plate or ball check valves. This reduction in components not only makes the design simpler but also contributes to a lower risk of mechanical failure.

Advantages of Single Plate Check Valves

1. Compact Design Single plate check valves are compact and lightweight, making them an excellent choice for applications where space is at a premium. Their streamlined design reduces the friction losses associated with the fluid flow, leading to increased efficiency.

2. Low Pressure Drop These valves are engineered to provide a low-pressure drop across the valve. This characteristic is crucial in systems where maintaining pressure is essential, such as in water distribution and chemical processing plants.

3. Quick Response Time Due to their design, single plate check valves respond quickly to changes in pressure. This rapid action minimizes the risk of water hammer effects—sudden surges in pressure that can cause significant damage in piping systems.

4. Cost-Effectiveness The simpler design translates into lower manufacturing costs, making single plate check valves more economical than more complex alternatives. Additionally, the reduced maintenance requirements due to fewer moving parts lead to long-term savings.

Applications of Single Plate Check Valves

Single plate check valves are widely used in various industries

. Their common applications includesingle plate check valve

- Water and Wastewater Management They are employed in pumping stations and water distribution systems to prevent backflow, ensuring the integrity of water supplies.

- Chemical Processing In chemical plants, these valves are crucial for maintaining the directional flow of hazardous or corrosive fluids, thereby enhancing safety and efficiency.

- HVAC Systems Single plate check valves are utilized in heating, ventilation, and air conditioning systems to prevent backflow in ductwork, helping to maintain optimal environmental conditions.

- Food and Beverage Industry Their easy cleaning and maintenance make them suitable for applications in food processing, where hygiene is of utmost importance.

Maintenance of Single Plate Check Valves

While single plate check valves are generally low maintenance, regular inspections are essential to ensure their optimal performance. Here are some maintenance tips

1. Routine Inspections Periodically check for wear, corrosion, or any damage to the disc and hinge. Replacing any worn components promptly will prevent leakage or valve failure.

2. Clear Debris Ensure that the valve seat and surrounding areas are free of debris or buildup that could impede the valve's operation.

3. Test Functionality Regularly test the valve's operation by checking for proper opening and closing under normal operating conditions, ensuring that it responds correctly to pressure changes.

4. Check for Leaks Inspect for any signs of leakage around the valve, which could indicate a failure of the sealing surfaces.

Conclusion

Single plate check valves are essential components in a variety of fluid systems, offering a balance of simplicity, efficiency, and reliability. Their compact design, low pressure drop, and quick response time make them suitable for many applications across different industries. With proper maintenance, these valves can provide long-lasting service, ensuring the integrity and efficiency of fluid systems. Understanding their role and functionalities can greatly enhance operational reliability and safety in various industrial processes.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025