Dec . 05, 2024 10:32 Back to list

grooved end butterfly valve

Grooved End Butterfly Valve An Overview

In the world of industrial valves, the grooved end butterfly valve stands out as a crucial component used to regulate the flow of liquids and gases in various applications. This type of valve is characterized by its unique construction, specifically designed with grooved ends, which facilitate easy installation and maintenance. The growing demand for efficient flow control mechanisms has led to the increased popularity and application of grooved end butterfly valves in diverse sectors, including water treatment, HVAC systems, and process industries.

Construction and Design

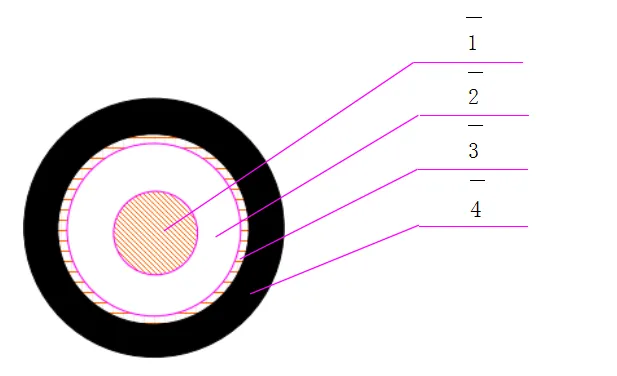

The grooved end butterfly valve consists of a circular disc or body that rotates around a central axis. The design features grooves on both ends of the valve, allowing it to connect seamlessly with piping systems through grooved couplings. This connection method offers several advantages, including enhanced sealing capabilities, reduced installation time, and the ability to withstand high-pressure conditions. The valve can be operated manually using a lever or automatically with an actuator, making it versatile for different operational needs.

The materials used in constructing grooved end butterfly valves vary depending on the application requirements

. Common materials include cast iron, stainless steel, and PVC, each chosen for its durability, resistance to corrosion, and ability to handle specific media types. Furthermore, the sealing materials within the valve often include elastomers and Teflon, which improve the valve's performance, ensuring minimal leakage and extended service life.Benefits of Grooved End Butterfly Valves

One of the primary advantages of grooved end butterfly valves is their ease of installation. The grooved connection eliminates the need for extensive welding or threading, making it a preferred choice in environments where time and efficiency are critical. Additionally, the lightweight construction of butterfly valves means that they can be installed in various settings without the need for heavy lifting equipment, making them suitable for both indoor and outdoor applications.

grooved end butterfly valve

Moreover, the grooved end design aids in reducing installation costs, as it requires less labor and time. Coupled with the fact that maintenance is simplified due to the ease of access to the valve components, grooved end butterfly valves can significantly lower the total cost of ownership in a piping system.

Another significant benefit lies in their flow control capabilities. The design of the butterfly valve allows for precise modulation of flow, making it ideal for applications that require careful regulation of liquid or gas. The quick operation of the valve ensures fast response times, essential in systems that demand immediate control over the media flow.

Applications

Due to their versatility, grooved end butterfly valves find applications across various industries. In water treatment facilities, they are commonly used to regulate the flow of water throughout various treatment stages. In HVAC systems, these valves help in managing airflow, ensuring optimal conditions within buildings. Additionally, chemical processing industries utilize butterfly valves to handle corrosive substances, taking advantage of their robust materials and design.

Conclusion

In summary, the grooved end butterfly valve is an essential component in modern piping systems due to its unique design and numerous benefits. Its ease of installation, low maintenance needs, and effective flow control capabilities make it a preferred choice in various industries. As industrial requirements evolve, the role of grooved end butterfly valves is set to expand, supporting the ongoing quest for efficiency and reliability in fluid management solutions. Whether you're involved in water treatment, HVAC, or chemical processing, understanding the advantages and applications of grooved end butterfly valves can lead to improved system performance and reduced operational costs.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025