Aug . 27, 2024 18:19 Back to list

Groove Check Valve | High Performance & Reliable Flow Control

Understanding Groove Check Valves Functionality and Applications

Groove check valves are crucial components widely used in various piping systems, designed to ensure the unidirectional flow of fluids. These valves help prevent reverse flow, safeguarding downstream equipment, and maintaining system efficiency. Featuring a unique grooved design, these check valves are appreciated for their ease of installation and reliable performance under various pressure conditions.

The primary function of a groove check valve is to allow fluid to flow in one direction only. When the fluid pressure exceeds the valve's set point, the valve opens, permitting flow. Conversely, if there’s a drop in pressure or a reversal in flow direction, the valve closes, effectively blocking the backflow. This characteristic makes groove check valves vital in systems such as water supply, drainage, and chemical processing, where backflow can lead to contamination or damage.

One notable advantage of groove check valves is their design, which often incorporates straightforward grooves that allow for quick installation and maintenance. These grooves enable the valve to connect easily with other piping components, reducing assembly time. Moreover, the simple construction of groove check valves often leads to lower costs compared to more complex valve alternatives.

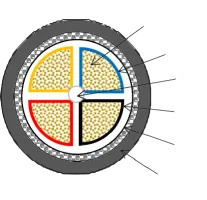

groove check valve

The material selection for groove check valves significantly affects their performance and durability. They can be manufactured from various materials, including brass, stainless steel, and PVC, allowing for versatility in different environments. For instance, stainless steel valves are ideal for corrosive applications, while PVC options are lightweight and suitable for low-pressure systems.

In terms of applications, groove check valves are commonly found in domestic plumbing, HVAC systems, irrigation, and industrial fluid transport. They are especially indispensable in applications that require a reliable barrier against backflow, such as in heating systems, where the risk of cooling water returning to the hot water supply could lead to inefficiencies and potential damage.

In summary, groove check valves play a vital role in various fluid handling systems by ensuring the proper direction of flow and protecting equipment from reverse flow. Their easy installation combined with a range of material choices makes them a preferred option in many applications. As fluid dynamics continue to evolve in the industrial landscape, the importance of reliable components like groove check valves will only grow, ensuring systems operate safely and efficiently. Understanding their functionality and applications can help engineers and technicians make informed decisions when selecting the right valve for a given system.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025