Nov . 07, 2024 19:36 Back to list

Flow Regulation and Monitoring Valve for Enhanced Performance and Efficiency

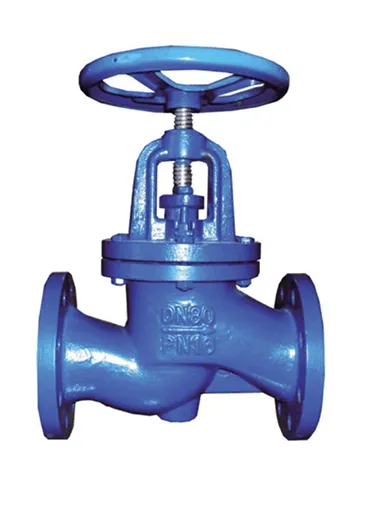

Understanding Flow Control Check Valves

Flow control check valves are essential components in many hydraulic and pneumatic systems. Their primary function is to regulate the flow of fluids in a system while preventing backflow. This dual functionality is crucial for maintaining system efficiency, safety, and performance. By understanding how these valves operate and their applications, we can appreciate their importance in various industries.

What is a Flow Control Check Valve?

A flow control check valve is a type of valve designed to manage the flow rate of fluid in one direction while automatically preventing backflow. Its construction typically consists of a body, an inlet and outlet port, and a mechanism (like a ball, disc, or flap) that allows the fluid to flow freely in the desired direction but closes when there is a reverse flow.

The term flow control indicates that not only does the valve ensure that fluid flows in one direction, but it also regulates the speed of that flow. This is particularly important in systems where excess flow can lead to equipment damage or inefficiencies.

How Do They Work?

The working principle of a flow control check valve revolves around pressure differentials and gravity. When fluid enters the valve from the inlet, it creates a pressure difference that causes the mechanism to open. Depending on the design, the flow can be further tuned using an adjustable throttling feature. When the flow stops or attempts to reverse, gravity or spring action closes the valve, preventing backflow.

This mechanism is particularly effective in applications requiring precise flow rates or where backflow could cause problems, such as in irrigation systems, fuel lines, and chemical processing plants.

Types of Flow Control Check Valves

There are several types of flow control check valves, each designed for specific applications

1. Ball Check Valves These have a spherical ball that moves up and down in the valve body. The ball allows fluid to flow in one direction but seals against the seat when flow attempts to reverse.

2. Disc Check Valves These utilize a disc that pivots or slides to allow or restrict flow. They are often used in larger pipelines where a quick response to flow changes is necessary.

3. Flap Check Valves Common in wastewater applications, these valves use a hinged flap to allow flow in one direction while preventing backflow.

4. Spring-Loaded Check Valves These incorporate a spring mechanism that holds the valve closed until a certain pressure is applied, ensuring a more controlled response to changes in flow conditions.

flow control check valve

Applications of Flow Control Check Valves

Flow control check valves are found in a variety of applications across multiple industries.

- Hydraulic Systems In hydraulic machinery, they help maintain fluid under pressure while preventing backflow that could affect system performance. - Water Treatment Plants They are critical in preventing the backflow of contaminated water into clean water supplies.

- Chemical Processing Controlling the flow rates of chemicals to ensure safe mixing and reaction conditions.

- Food and Beverage Industry Ensuring that products move through processing systems without the risk of contamination from backflow.

- Irrigation Systems Protecting pumps and ensuring consistent delivery of water to crops.

Benefits of Using Flow Control Check Valves

The use of flow control check valves brings numerous benefits

1. Increased Safety By preventing backflow, these valves help to avoid dangerous situations that could cause spills or contamination.

2. Lower Maintenance Costs With better flow regulation, systems operate more efficiently, reducing wear and tear on equipment.

3. Regulatory Compliance Many industries are subject to regulations regarding the handling of fluids. Flow control check valves help ensure compliance with these standards.

4. Enhanced System Performance By providing reliable control of flow rates, these valves help maintain optimal performance across various systems.

Conclusion

Flow control check valves are pivotal in ensuring the smooth operation of fluid systems. With their ability to regulate flow rates and prevent backflow, they play a vital role in various industries, contributing to safety, efficiency, and compliance. As technology continues to evolve, advancements in valve design will further enhance their functionality, leading to even broader applications and improved operational performance. Therefore, understanding and utilizing flow control check valves is fundamental for anyone involved in fluid management systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025