Aug . 30, 2024 09:51 Back to list

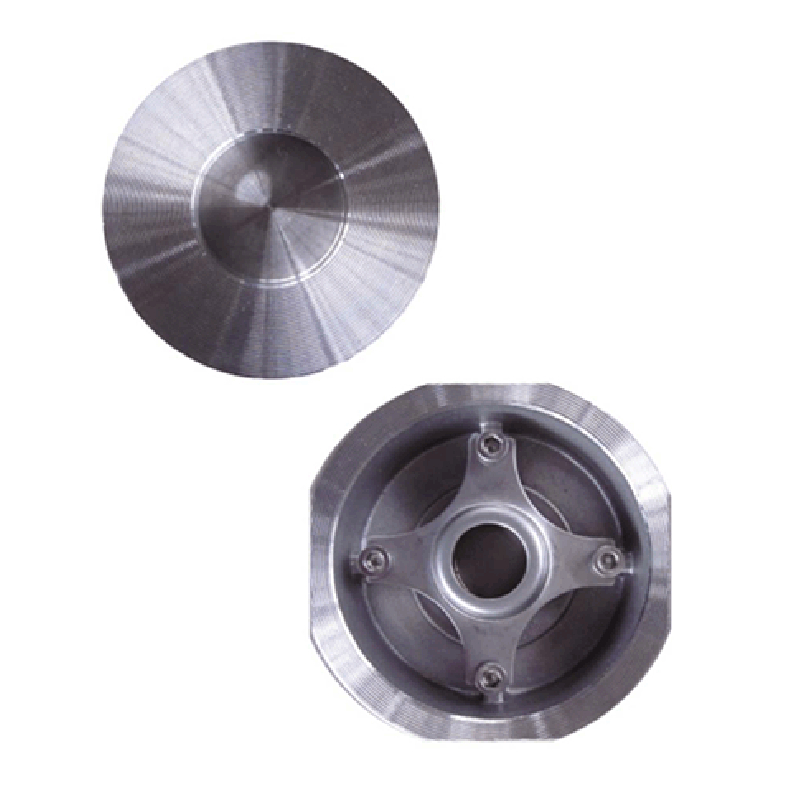

High-Quality Ductile Iron Globe Valve - Durable & Reliable

Ductile Iron Globe Valves A Comprehensive Overview

Ductile iron globe valves are vital components in various industrial applications, providing crucial control over fluid flow in pipelines. Manufactured from high-strength ductile iron, these valves offer enhanced durability and strength compared to their cast iron counterparts. The unique characteristics of ductile iron allow for thinner walls, reducing the overall weight of the valve while maintaining excellent resilience against pressure and temperature variations.

One of the primary advantages of ductile iron globe valves is their ability to withstand high pressures and harsh environments. This makes them ideal for use in industries such as water treatment, oil and gas, and power generation. Their design typically features a spherical body, which enables efficient flow regulation. The flow control mechanism is facilitated by a movable disk that can be adjusted to create varying degrees of resistance against the fluid flow, thus effectively regulating the passage of liquids or gases.

The construction of ductile iron globe valves also emphasizes safety and reliability

. Many models are equipped with a pressure sealing design that prevents leaks, ensuring that hazardous fluids are contained within the system. Additionally, their robust construction minimizes the risk of failure under extreme operational conditions, thus enhancing the safety profile of systems where they are installed.ductile iron globe valve

Another important characteristic of ductile iron globe valves is their versatility in terms of operation. They can be manually operated or automated, allowing for seamless integration into existing pipeline systems. Automated versions can be controlled remotely, improving efficiency and accuracy in fluid management across large networks.

Maintenance of these valves is relatively straightforward. Regular inspections can help identify wear and tear, and replacement parts are typically readily available. This not only extends the service life of the valve but also ensures minimal downtime in industrial operations.

Moreover, ductile iron globe valves are often coated with various finishes to enhance corrosion resistance, further extending their life expectancy. Whether operating in fresh water, seawater, or harsh chemical environments, the right coating can protect the valve from the degrading effects of constant exposure to harsh conditions.

In conclusion, ductile iron globe valves are essential components commonly utilized across diverse industries for their robustness, safety, and operational efficiency. Their ability to withstand demanding conditions while providing precise control over fluid flow makes them a preferred choice for engineers and plant operators alike. As industries continue to evolve, these valves will undoubtedly play an integral role in meeting the challenges associated with modern fluid handling systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025