Ott . 06, 2024 07:37 Back to list

rubber flapper check valve

Rubber Flapper Check Valve An Essential Component in Fluid Systems

A rubber flapper check valve is a critical device utilized in various fluid systems to ensure one-way flow and prevent backflow, which can lead to system inefficiencies and potential damage. These valves are engineered for robust performance in a wide range of applications, from municipal water systems to industrial machinery.

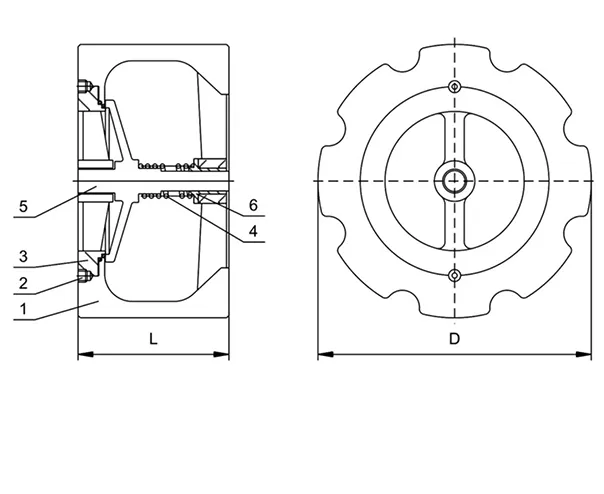

The design of a rubber flapper check valve is relatively simple yet effective. It typically consists of a valve body, a flapper, and a seat. The flapper, made from high-quality rubber, is hinged at the top and is free to pivot. When fluid flows in the intended direction, the flapper opens to allow passage. However, if the flow reverses, the flapper closes tightly against the seat, creating a seal that stops any backflow. This reliable mechanism is essential in maintaining the integrity of fluid systems and ensuring continuous operation.

One of the primary advantages of rubber flapper check valves is their ability to withstand a variety of chemicals and conditions. The rubber material used in the flapper is often resistant to corrosion, making these valves suitable for applications involving harsh chemicals or abrasive materials. Additionally, the flexibility of rubber provides a better sealing capability compared to metal counterparts, reducing the risk of leaks and enhancing overall performance.

rubber flapper check valve

Installation of rubber flapper check valves is straightforward, which contributes to their popularity in both residential and industrial settings. They can be placed vertically or horizontally, providing flexibility in system design. However, it is crucial to ensure that they are installed in the correct orientation to function effectively. Proper installation not only maximizes their efficiency but also extends their lifespan.

In terms of maintenance, rubber flapper check valves are relatively low-maintenance components. Periodic inspections are recommended to ensure the mechanism operates smoothly and that the rubber material has not degraded due to prolonged exposure to fluids or environmental conditions. Any signs of wear or damage should be addressed promptly to avoid system failures.

The application of rubber flapper check valves extends beyond traditional plumbing systems. They are also utilized in various industrial processes, including wastewater management, chemical processing, and even agricultural irrigation systems. In these contexts, their ability to prevent backflow is crucial in protecting pumps and other equipment from potential damage and inefficiencies caused by reverse flow.

In conclusion, the rubber flapper check valve is an indispensable component in modern fluid systems. Its simple yet effective design, combined with the durability and versatility of rubber, makes it a favored choice in various applications. By ensuring one-way flow and preventing backflow, these valves enhance system reliability and efficiency, making them essential in maintaining the integrity of fluid management systems across multiple industries. As technology advances, further innovations in check valve design and materials will continue to improve their performance and applicability.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025