nóv . 18, 2024 23:16 Back to list

Wafer and Lug Style Butterfly Valve Comparison and Application Guide

Wafer and Lugged Butterfly Valves An Overview

Butterfly valves are critical components in a wide variety of industrial applications, employed primarily for regulating flow in pipelines. Among the various designs of butterfly valves, wafer and lugged butterfly valves are two commonly used types, each with unique features and benefits that cater to specific application needs.

What are Butterfly Valves?

Butterfly valves consist of a circular disc that rotates around a central axis to control fluid flow. The simplicity of their design allows for quick operation, reliability, and a compact footprint, making them ideal for a range of medium to large-scale operations. These valves excel in applications including water treatment, chemical processing, HVAC systems, and more.

Wafer Butterfly Valves

Wafer butterfly valves are characterized by their design, which consists of a disc mounted between two flanges without the need for bolts to connect the valve to the pipeline. Instead, the valve is designed to fit snugly between the flanges of the piping system. This design feature facilitates ease of installation and reduces the overall weight and cost of the valve.

Advantages of Wafer Butterfly Valves

1. Space Efficiency Their compact design allows for installation in tight spaces. The wafer design minimizes the need for additional space, making it an excellent choice for applications where horizontal or vertical space is limited.

2. Cost-Effectiveness Because wafer valves do not require additional bolting hardware, they often present a lower overall cost compared to other valve types.

3. Low Torque Requirement They require minimal torque to operate, which often leads to the need for smaller actuators, further enhancing cost efficiency.

4. Versatility Wafer butterfly valves can be manufactured to handle a variety of flow media, from liquids to gases, and they can be made from various materials such as stainless steel, plastic, or cast iron depending on the application requirements.

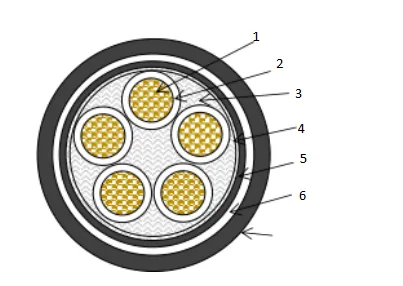

wafer and lugged butterfly valve

Lugged Butterfly Valves

Unlike wafer butterfly valves, lugged butterfly valves feature threaded lugs on the valve body that allow for bolts to be used to secure the valve to the pipeline

. This design enables the valve to be installed on flanged pipes independently or to be removed without the need to remove the entire pipeline.Advantages of Lugged Butterfly Valves

1. Easy Maintenance The lugged design simplifies maintenance work because the valve can be easily removed for service without disrupting the adjoining piping.

2. Independent Installation Lugged valves can be installed in piping systems that are not aligned, allowing for greater flexibility in valve placement in existing systems.

3. Robust Design The threaded lugs provide increased structural integrity and stability compared to wafer designs, making them more suitable for high-pressure applications or situations where the valve may experience vibration or movement.

4. Wide Application Scope Lugged butterfly valves are commonly used in systems that require bi-directional flow, including wastewater treatment, fire protection systems, and many industrial processes.

Choosing the Right Valve

Selecting between wafer and lugged butterfly valves largely depends on the specific requirements of the application. Key factors to consider include the nature of the fluid, pressure conditions, installation environment, and maintenance needs. Understanding these factors can help engineers and system designers make informed decisions that enhance operational efficiency and reliability.

Conclusion

Wafer and lugged butterfly valves serve distinct roles in industrial applications, each offering unique benefits tailored to specific contexts. By understanding the differences between these two types of valves, industry professionals can select the appropriate solution for their piping needs, ensuring optimal performance and longevity. As technology continues to advance, the designs of butterfly valves are also evolving, which will likely bring about even greater efficiency and sustainability in fluid handling systems across various sectors.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025