des . 11, 2024 21:26 Back to list

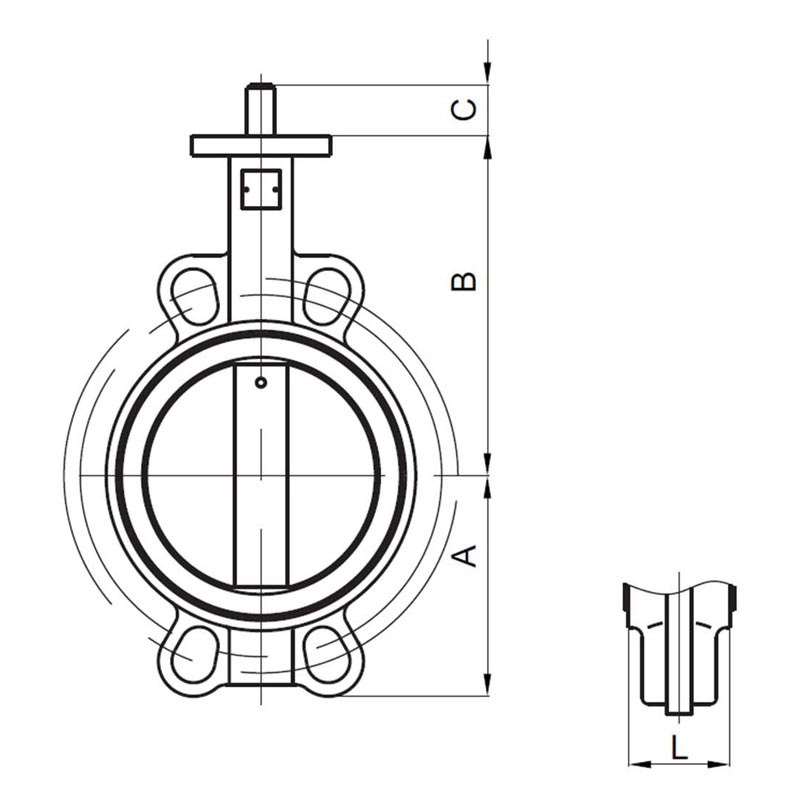

semi lugged butterfly valve

Understanding the Semi-Lugged Butterfly Valve A Comprehensive Guide

In the realm of industrial fluid control, valves play a crucial role in regulating the flow of liquids and gases. Among the various types of valves available, the semi-lugged butterfly valve stands out due to its unique design and operational advantages. This article aims to elucidate the characteristics, applications, and benefits of the semi-lugged butterfly valve.

What is a Semi-Lugged Butterfly Valve?

The semi-lugged butterfly valve is a quarter-turn valve that utilizes a circular disc or butterfly to control the flow. The term semi-lugged refers to the way this valve is designed. Unlike fully lugged valves, which have threaded lugs for secure mounting, the semi-lugged design allows for a more versatile installation while maintaining a streamlined structure. This feature is particularly beneficial in spaces where working with a limited amount of room is a concern.

The valve consists of three main components the body, the disc, and the actuator. The body serves as the housing for the disc and is typically made from materials such as stainless steel, cast iron, or PVC, each chosen based on the application and media compatibility. The disc pivots around a central axis to either open or close the flow path. Actuators—whether manual, pneumatic, or electric—provide the necessary force to position the disc accurately.

Key Features

1. Compact Design The semi-lugged butterfly valve boasts a lightweight and compact structure, which makes it ideal for installations with space constraints. This design reduces the overall footprint compared to traditional gate or globe valves.

2. Ease of Installation The semi-lugged feature enhances the ease of installation by permitting mounting on various pipe sizes without requiring costly modifications. The alignment guides facilitate accurate positioning, ensuring a tight seal and reducing potential leak paths.

3. Flow Control The butterfly design allows for quick and efficient flow regulation. By rotating the disc approximately 90 degrees, the user can completely open or close the valve in a fraction of a second. This feature is especially useful in processes requiring rapid adjustments to flow rates.

4. Versatility These valves can be used in both on-off and throttling applications, making them versatile tools in different industrial contexts. Their flexibility allows for use in various sectors, including water treatment, chemical processing, and HVAC systems.

Applications

semi lugged butterfly valve

The applications for semi-lugged butterfly valves are diverse, depicting the valve's adaptability to various industries and media

.- Water and Wastewater Treatment In municipal water systems, these valves effectively manage flow in pipelines, treatment tanks, and irrigation systems.

- Chemical Processing Given their resistance to corrosion and ability to handle different chemicals, semi-lugged butterfly valves are widely used in chemical plants for controlling the flow of aggressive substances.

- HVAC Systems In heating, ventilation, and air conditioning systems, they regulate airflow, contributing to energy efficiency and system performance.

- Food and Beverage Sanitary versions of the valve are preferable in food processing applications where cleanliness and hygiene are paramount.

Benefits

The use of semi-lugged butterfly valves provides numerous benefits

- Reduced Maintenance Costs Their robust design and fewer moving parts lead to lower maintenance needs, thereby reducing operational costs over time. - Improved Performance The efficient flow characteristics minimize pressure drops, which can significantly enhance the overall performance of fluid transport systems.

- Cost-Effectiveness The affordability and ease of installation of these valves make them a cost-effective choice for many applications.

Conclusion

In conclusion, the semi-lugged butterfly valve is a highly efficient and versatile solution for fluid control in various industrial applications. Its compact design, ease of installation, and adaptability make it a preferred choice for engineers and operators alike. As industries continue to evolve, the demand for reliable and efficient fluid handling solutions like the semi-lugged butterfly valve will undoubtedly increase, solidifying its importance in modern engineering practices.

Share