feb . 11, 2025 11:42 Back to list

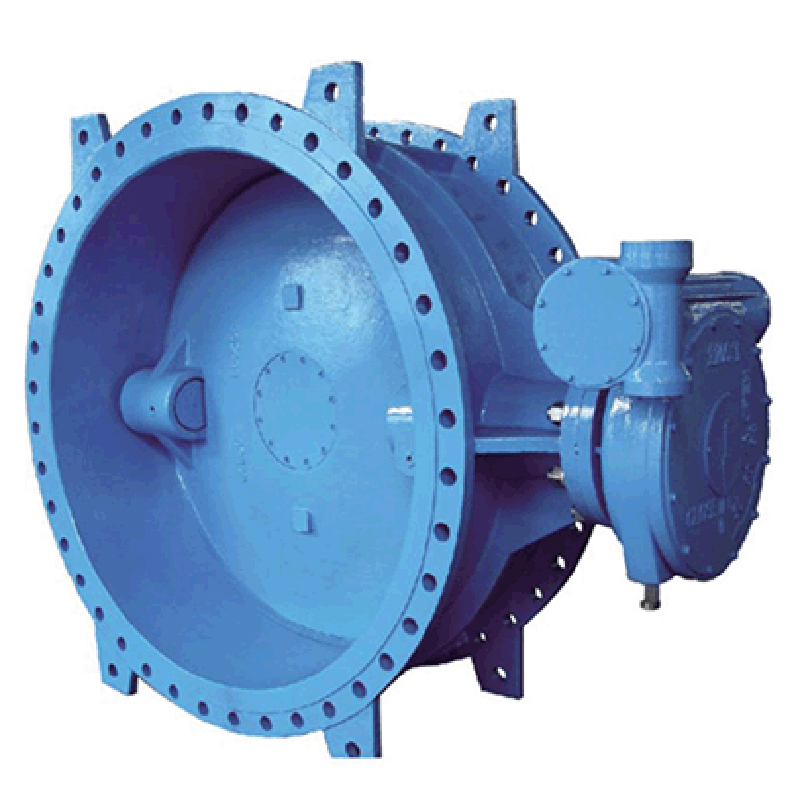

knife gate valve

Knife gate valves have become an essential component in a wide range of industries due to their unique design and functionality. Originating from the pulp and paper industry, where their ability to cut through heavy liquids was invaluable, these valves are now used across many sectors including wastewater treatment, food and beverage processing, and mining.

Moreover, its integration with advanced control systems further enhances its authority in automated process control environments. By offering precision and reliability, knife gate valves contribute significantly to maintaining the integrity of complex systems, assuring stakeholders of optimized process control and resource management. The sustainability aspect of knife gate valves cannot be overstated. By minimizing leaks and ensuring precise control of media flow, they play a crucial role in reducing waste and enhancing energy efficiency—making them a preferred choice for industries aspiring to operate sustainably. This transition towards more eco-friendly operations hints at the growing trust professionals place in products that align with environmental goals, reinforcing their trustworthiness. Quality adherence in the production of knife gate valves showcases commitment to excellence. Manufacturers frequently adhere to stringent industry standards such as API, ASME, and ISO, ensuring products meet global benchmarks for safety and performance. This dedication to maintaining high standards not only elevates the product’s credibility but also aligns with global best practices. Discussing the future prospects of knife gate valves involves exploring innovations aimed at enhancing performance and reducing costs. Potential areas of advancement include material innovations for higher durability and improved sealing technologies to expand applications in even more strenuous environments. This pursuit of innovation underscores the industry’s expertise and commitment to adapting to ever-evolving industrial challenges. In conclusion, the expertise embodied in knife gate valve design and application, combined with their proven authority and the trust they command across industries, positions them as indispensable tools in modern industrial processes. As they continue to evolve, their role in optimizing efficiency and supporting sustainable practices assures their standing as not just components, but pivotal instruments of industrial success.

Moreover, its integration with advanced control systems further enhances its authority in automated process control environments. By offering precision and reliability, knife gate valves contribute significantly to maintaining the integrity of complex systems, assuring stakeholders of optimized process control and resource management. The sustainability aspect of knife gate valves cannot be overstated. By minimizing leaks and ensuring precise control of media flow, they play a crucial role in reducing waste and enhancing energy efficiency—making them a preferred choice for industries aspiring to operate sustainably. This transition towards more eco-friendly operations hints at the growing trust professionals place in products that align with environmental goals, reinforcing their trustworthiness. Quality adherence in the production of knife gate valves showcases commitment to excellence. Manufacturers frequently adhere to stringent industry standards such as API, ASME, and ISO, ensuring products meet global benchmarks for safety and performance. This dedication to maintaining high standards not only elevates the product’s credibility but also aligns with global best practices. Discussing the future prospects of knife gate valves involves exploring innovations aimed at enhancing performance and reducing costs. Potential areas of advancement include material innovations for higher durability and improved sealing technologies to expand applications in even more strenuous environments. This pursuit of innovation underscores the industry’s expertise and commitment to adapting to ever-evolving industrial challenges. In conclusion, the expertise embodied in knife gate valve design and application, combined with their proven authority and the trust they command across industries, positions them as indispensable tools in modern industrial processes. As they continue to evolve, their role in optimizing efficiency and supporting sustainable practices assures their standing as not just components, but pivotal instruments of industrial success.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025