nóv . 05, 2024 10:07 Back to list

knife gate valve

Understanding Knife Gate Valves Their Design, Function, and Applications

Knife gate valves are specialized types of valves that are primarily used to regulate or isolate the flow of fluids in various industrial applications. These valves are designed to handle slurries, viscous fluids, and solids, making them a popular choice in industries such as wastewater treatment, mining, pulp and paper, and food processing. This article explores the design, operation, advantages, and applications of knife gate valves.

Design Features

The knife gate valve is distinctively engineered to provide optimal performance in challenging environments. Its construction typically includes a sharp-edged blade, or knife, that effectively cuts through materials like slurries or granular substances when the valve is opened. The knife blade is often made from durable materials such as stainless steel or hardened steel, allowing for resilience against abrasive materials.

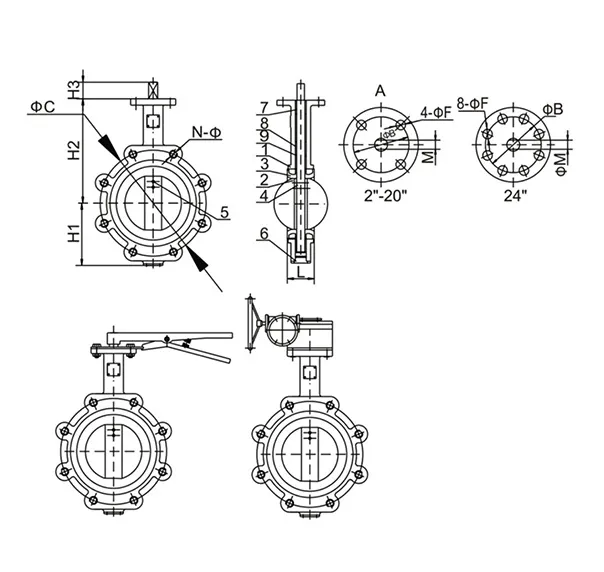

One of the defining features of a knife gate valve is its body design, which is usually made from cast iron, carbon steel, or other robust materials. The body usually has a simple connection mechanism such as flanged ends, which makes it easy to install and maintain. Knife gate valves can also come in two main configurations rising stem and non-rising stem variants. In a rising stem design, the actuator visibly moves upward as the valve opens, providing a clear indication of the valve's position.

Functionality and Operation

Knife gate valves operate using a simple mechanism involving a gate that moves up and down to control the flow. When the valve is in the closed position, the knife blade cuts through the medium, creating a tight seal. This design minimizes the potential for leakage, particularly in applications where containment is critical.

To operate a knife gate valve, a manual or automated actuator is attached

. This can include handwheels, electric actuators, pneumatic cylinders, or hydraulic systems, depending on the requirements and level of automation desired. The simplicity of its operation makes it a preferred choice in systems where space is constrained, or quick on-off control is necessary.Advantages of Knife Gate Valves

knife gate valve

Knife gate valves offer numerous advantages that make them suitable for various applications. They are particularly effective in handling thick slurries and solids, which many traditional valve types struggle with. Their ability to cut through such materials allows for both flow regulation and reliable isolation.

Additionally, knife gate valves are relatively easy to maintain due to their straightforward design. The reduced number of moving parts minimizes wear and tear, which contributes to a longer service life. Another advantage is their space-efficient design, making them an excellent choice for installations with limited space.

The ability to operate in high-pressure and high-temperature environments adds to their versatility. Many knife gate valves are also engineered to resist corrosion and erosion, thus ensuring durability even under harsh operating conditions.

Applications Across Industries

Knife gate valves find applications in a multitude of industries. In the wastewater treatment sector, they are commonly used to control the flow of sludge and other viscous materials. The mining industry frequently employs them to manage the flow of ores and other particulate materials.

In the pulp and paper industry, knife gate valves are utilized to control processes that involve significant solid-liquid mixtures. They are also standard in food processing, where they help in the transportation of various materials without contamination.

The versatility of knife gate valves also extends to the energy sector, where they are employed in utilities and power generation systems. Their ability to handle a range of fluids makes them suitable for applications involving both water and steam.

Conclusion

In summary, knife gate valves are crucial components in various industrial processes, offering benefits in handling challenging materials with ease. Their unique design, coupled with operational efficiency and minimal maintenance requirements, positions them as a valuable asset in multiple sectors. As industries continue to evolve and demand higher performance levels, the importance of knife gate valves is likely to increase, cementing their role as essential tools for effective flow control.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025