des . 01, 2024 07:52 Back to list

Foot Valve with Integrated Strainer for Improved Fluid Control and Efficiency

Understanding Foot Valves with Strainers Importance and Functionality

Foot valves with strainers are crucial components in various fluid systems, primarily in water pumping applications. Designed to prevent backflow and ensure the efficient operation of pumps, these devices play a pivotal role in maintaining system integrity. To comprehend their significance, it is essential to unravel the mechanics behind foot valves and strainers, and their collective impact on fluid management.

Basics of Foot Valves

A foot valve is a type of check valve installed at the bottom end of a pump suction line. Positioned underwater, it serves two primary purposes. First, it prevents the backflow of water, ensuring that the pump remains primed—critical for efficient operation. Second, it facilitates the smooth entry of water into the pump when it operates, allowing for a continuous flow. Foot valves are especially important in applications where pumps are situated away from the water source, as they help maintain prime during operational downtimes.

The Role of Strainers

Strainers are used in conjunction with foot valves to filter out unwanted debris, mud, and other particulates from entering the pumping system. By trapping large particles and sediments, strainers protect the foot valve and subsequent pump components from clogging and potential damage. This filtration is particularly important in environments where the water source may contain sand, leaves, or other organic matter That can hinder the pump's efficiency and longevity.

Design and Materials

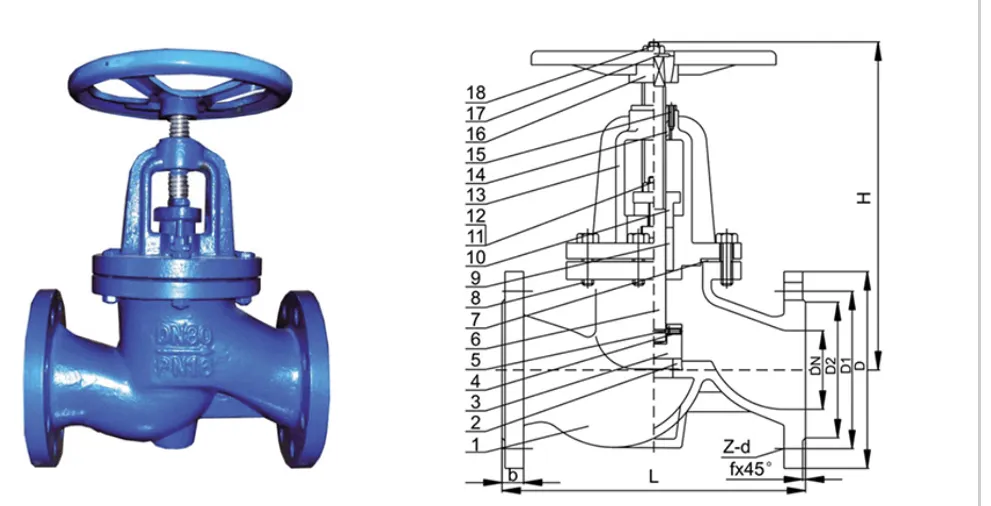

Foot valves with strainers come in various designs, but they typically feature a cylindrical body with a built-in strainer at the entry point. The strainer's mesh size can vary depending on the specific application and the types of debris anticipated in the water source. Common materials used for foot valves include brass, PVC, and stainless steel, each selected based on durability requirements and the nature of the fluid being pumped.

Installation and Maintenance

foot valve with strainer

Proper installation is crucial for the effective performance of foot valves. They should be placed at a depth where they can draw water without obstruction from sediments settling at the bottom. Regular maintenance is also essential; inspecting the strainer for clogs and replacing it as necessary ensures that the foot valve operates efficiently over time. Neglected strainers can lead to decreased pump performance and increased energy consumption.

Advantages of Using Foot Valves with Strainers

The integration of a foot valve with a strainer offers several advantages

1. Protection from Contaminants By filtering out debris, it reduces the risk of damage to pumps and associated components. 2. Efficiency in Operation Preventing backflow keeps the pump primed, which is essential for maintaining optimal flow rates and reducing energy usage.

3. Extended Equipment Lifespan Properly managed systems with foot valves and strainers tend to have longer operational lifespans, minimizing maintenance costs and downtime.

4. Versatility Foot valves with strainers can be used in numerous applications, from agricultural irrigation systems to industrial fluid management, making them indispensable in various fields.

Conclusion

In conclusion, foot valves with strainers are integral to fluid management systems, ensuring that pumps operate efficiently while safeguarding against contaminants. Their simple yet effective design serves vital functions that enhance the performance and longevity of pumping systems. Whether in agriculture, construction, or municipal water supply, understanding and efficiently utilizing foot valves with strainers can significantly impact operational success and sustainability. As industries continue to evolve, the role of these components will remain critical in managing water resources effectively.

Share

-

Y Strainers: Protecting Your Pipes with PrecisionNewsAug.27,2025

-

Wafer Type Butterfly Valves: Reliable Flow Control SolutionsNewsAug.27,2025

-

Wafer Type Butterfly Valves: Essential Components for Efficient Flow ControlNewsAug.27,2025

-

Reliable Flow Control with High-Quality Check ValvesNewsAug.27,2025

-

Reliable Flow Control with Gate ValvesNewsAug.27,2025

-

Innovative Check Valves for Reliable Flow ControlNewsAug.27,2025