des . 16, 2024 06:46 Back to list

Flanged Swing Check Valve Overview and Applications in Industrial Systems

Understanding Flanged Swing Check Valves A Comprehensive Guide

Flanged swing check valves are integral components widely used in various piping systems across industries. They play a critical role in ensuring the smooth and safe flow of fluids while preventing backflow, thereby protecting equipment and maintaining system integrity. This article delves into the design, functionality, applications, and advantages of flanged swing check valves.

Design and Construction

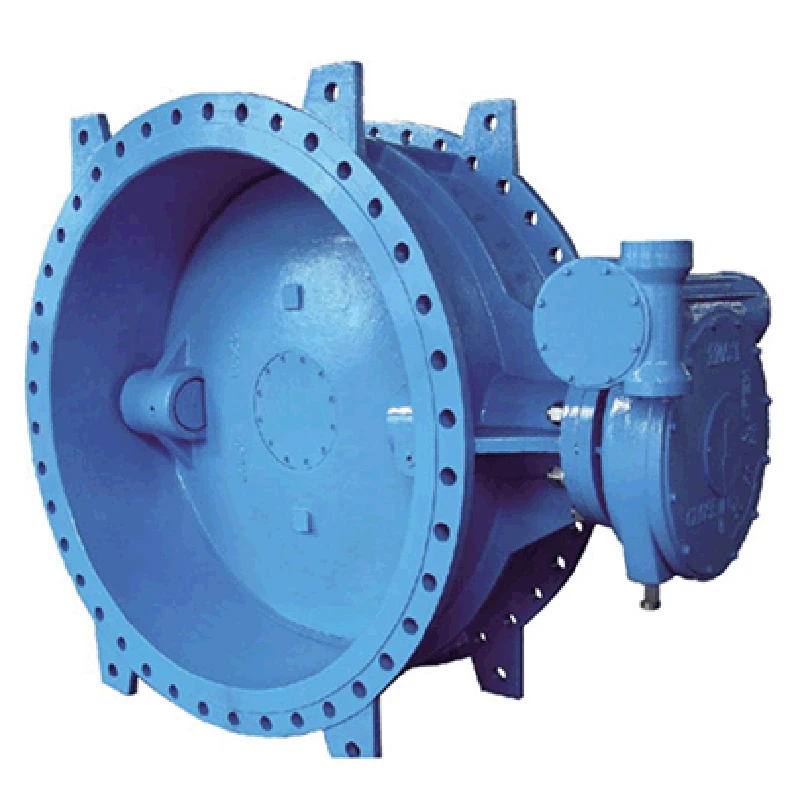

Flanged swing check valves are designed with a swinging disc that pivots on a hinge. The valve features flanged connections that allow for easy installation into piping systems. Commonly constructed from materials such as stainless steel, cast iron, or brass, the choice of material often depends on the specific application and the nature of the fluid being controlled. The design allows for minimal pressure drop, making them efficient in various operational settings.

The valve's primary components include the body, disc, hinge, and flanged connections. When fluid flows in the desired direction, the disc swings open, allowing passage. However, when the flow direction reverses, the disc swings closed due to gravitational force, sealing the valve and preventing backflow. This simple yet effective mechanism is crucial in many applications, ensuring that the operational integrity of the system is maintained.

Functionality

The primary function of a flanged swing check valve is to prevent backflow in pipelines. Backflow can cause significant damage to equipment, leading to costly repairs and potential safety hazards. By automatically closing when flow reverses, these valves act as a safeguard for pumps, compressors, and other critical components within a system. Their simple design means they have fewer mechanical parts, which translates to lower maintenance costs and extended service life.

Applications

flanged swing check valve

Flanged swing check valves are versatile and are used in a range of industries including water treatment, oil and gas, power generation, and chemical processing. They are particularly effective in applications where the fluid flow is primarily in one direction and where space allows the installation of a swinging mechanism.

In water treatment facilities, for example, these valves ensure that water flows in the correct direction through treatment processes, protecting sensitive equipment from damage. In the oil and gas industry, they are essential for maintaining pressure and preventing backflow that could lead to spills or leaks.

Advantages

One of the major advantages of flanged swing check valves is their efficiency. With a low pressure drop across the valve, they facilitate a smooth flow of fluids, resulting in more energy-efficient operations. Their design also allows for high flow capacity, making them suitable for larger pipelines.

Furthermore, their flanged connections provide a strong and secure method of fitting into existing piping systems, which can simplify installation and enable easier replacement when necessary. The lack of a stem and seat mechanism also reduces the likelihood of wear and tear, further extending the lifespan of these valves.

Another significant benefit is their automatic operation. Unlike manual valves, flanged swing check valves require no external power or control systems. They respond dynamically to changes in flow, making them ideal for environments where backflow may occur unexpectedly.

Conclusion

In summary, flanged swing check valves are vital components in many industrial applications, offering reliability, efficiency, and protection against backflow. Their design simplifies installation and maintenance while ensuring optimal fluid flow. As industries continue to evolve, the reliance on robust pipeline components such as flanged swing check valves will undoubtedly grow, underscoring their importance in maintaining system integrity and operational efficiency. Understanding their functionality and applications can help engineers and operators make informed decisions about their use in various piping systems, leading to safer and more efficient operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025