nóv . 29, 2024 16:16 Back to list

Flanged Gate Valve Design Specifications and Applications in Industrial Settings

Understanding Flanged Gate Valves Function, Benefits, and Applications

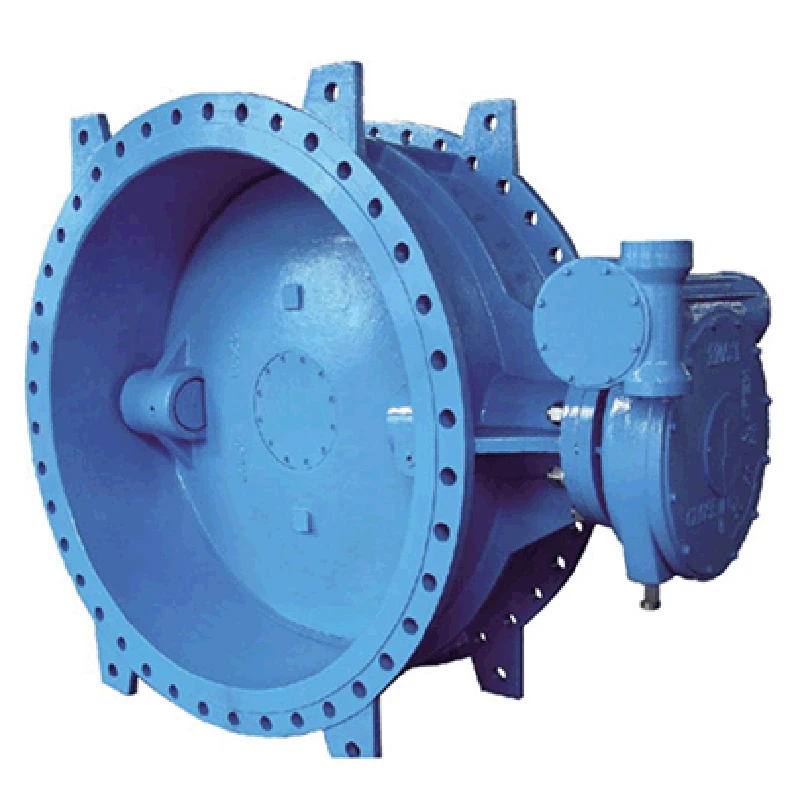

Flanged gate valves are essential components in piping systems, designed to control the flow of fluids such as water, oil, and gas. They are particularly favored for their reliability and ability to provide a tight seal when closed. This article explores the structure, function, advantages, and applications of flanged gate valves, shedding light on why they are a preferred choice in various industries.

Structure and Function

Flanged gate valves operate based on a simple mechanism that includes a gate or a wedge that moves vertically within the valve body. The valve features flanges on either end, which allow it to be bolted to other piping components. The gate is typically made of metal and is designed to provide a minimal obstruction to flow when fully opened. The unique design ensures that the valve can open and close with relative ease and is capable of handling high-pressure conditions.

The flanged design facilitates easy installation and maintenance. Since the flanges allow for secure connections, they eliminate the risk of leakage and improve the overall sealing capability of the pipeline system. When the valve is closed, the gate completely blocks the flow, while in the open position, it allows the fluid to pass through without any resistance, making it a highly efficient component.

Advantages of Flanged Gate Valves

One of the primary advantages of flanged gate valves is their ability to create a tight seal. This is crucial in preventing leaks and ensuring the safe transport of hazardous materials. They are also suitable for high-pressure and high-temperature applications, making them versatile in various industrial settings.

flanged gate valve

Another advantage is their low pressure drop, which means that there will be minimal energy loss when the fluid flows through the valve. The design of the valve allows for smooth passage, reducing turbulence and wear on the system. This is particularly beneficial in systems where flow efficiency is critical.

Additionally, flanged gate valves are known for their longevity and durability. The materials used in their construction can resist corrosion and other environmental factors, ensuring a longer lifespan. This durability translates to reduced maintenance costs, making flanged gate valves a cost-effective choice over time.

Applications

Flanged gate valves are widely used across a range of industries. In the water supply and wastewater treatment sectors, they play a crucial role in regulating flow and isolating sections of the system for maintenance. Similarly, in oil and gas industries, these valves manage the flow of crude oil and natural gas, ensuring safe and efficient transport.

In chemical processing, flanged gate valves are favored for their ability to handle corrosive substances. Their robust design and reliability make them an ideal choice for pipelines carrying chemicals, ensuring safety and efficiency. Flanged gate valves are also commonly used in power plants, where they help control steam flow and assist in thermal regulation.

Conclusion

In summary, flanged gate valves are vital components in various piping systems, offering significant advantages in terms of efficiency, durability, and reliability. Their unique design allows for easy installation and maintenance, while their tight sealing capabilities prevent leaks and ensure safe operation. With wide-ranging applications across multiple industries, flanged gate valves continue to be a preferred choice for engineers and operators striving for optimal performance in fluid management systems. Understanding their function and advantages can help in making informed decisions when selecting the right valves for specific applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025