des . 13, 2024 14:59 Back to list

Understanding the Functionality and Benefits of Butterfly Check Valves in Fluid Systems

Understanding Butterfly Check Valves A Comprehensive Overview

In the realm of fluid mechanics and engineering applications, valves play a critical role in controlling the flow of liquids and gases. Among various types of valves, the butterfly check valve stands out due to its unique design and functionality. This article explores the butterfly check valve, its working mechanism, advantages, applications, and maintenance considerations.

What is a Butterfly Check Valve?

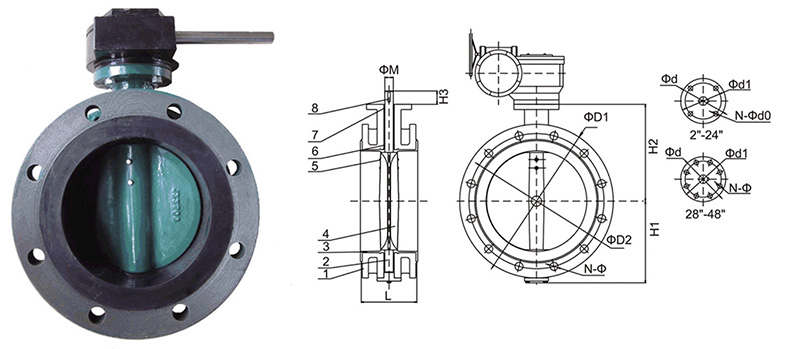

A butterfly check valve is a type of one-way valve that uses a rotating disc to allow or block the flow of fluid. Unlike traditional check valves, which often feature a spring-loaded or flap mechanism, butterfly check valves leverage a disc that pivots on a central axis. This disc opens when fluid flows in the desired direction and closes when the flow reverses, preventing backflow.

Working Mechanism

The operation of a butterfly check valve is relatively straightforward. When fluid flows in the forward direction, it exerts pressure on the disc, causing it to rotate and open. This allows the fluid to pass through the valve unobstructed. However, if the flow direction reverses, the fluid pressure decreases, causing the disc to return to its closed position, thereby sealing off the flow. This simple yet effective mechanism is what makes butterfly check valves popular in various applications.

Advantages of Butterfly Check Valves

1. Compact Design Butterfly check valves are known for their slim profile, which requires less space compared to other valve types. This makes them ideal for installations where space is a constraint.

3. Low Pressure Drop The streamlined design allows for minimal resistance to flow, resulting in lower pressure drops across the valve. This enhances the efficiency of fluid transport systems.

4. Versatility Butterfly check valves can handle a wide range of fluids, from water and wastewater to corrosive chemicals, making them versatile for various industries.

butterfly check valve

5. Maintenance-Friendly The simple design of butterfly check valves often translates to lower maintenance requirements compared to more complex valve designs.

Applications

Butterfly check valves are widely used in numerous industries due to their versatility and reliability. Common applications include

- Water Treatment They are employed in water distribution systems to prevent backflow and ensure efficient flow management.

- Chemical Processing In industries handling corrosive substances, butterfly check valves are crucial for maintaining process integrity and safety.

- HVAC Systems These valves are used in heating, ventilation, and air conditioning systems to regulate airflow and prevent backdrafts.

- Food and Beverage The sanitary design of butterfly check valves makes them suitable for food processing applications, where hygiene is paramount.

Maintenance Considerations

While butterfly check valves are generally low-maintenance, periodic checks are essential to ensure optimal performance. Regular inspection for wear and tear, particularly on the seat and disc, can prevent failures. Additionally, ensuring that the valve is installed correctly and is free from debris is crucial to maintain its functionality.

Conclusion

Butterfly check valves are an integral component in fluid control systems across various industries. Their efficient design, ease of use, and range of applications make them a preferred choice for engineers and technicians. As technology continues to evolve, the butterfly check valve remains a reliable solution for preventing backflow and ensuring the smooth operation of fluid systems. Understanding their mechanics and maintenance can help in optimizing their performance, thereby contributing to the overall efficiency of industrial processes.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025