Nov . 14, 2024 16:29 Back to list

wafer type butterfly valve flange

The Importance of Wafer Type Butterfly Valves with Flanges in Industrial Applications

In the world of fluid control, butterfly valves have emerged as a popular choice for various industries due to their efficiency and space-saving design. Among the different types of butterfly valves available, wafer type butterfly valves fitted with flanges have gained significant attention. This article delves into the features, benefits, and applications of wafer type butterfly valves with flanged connections, highlighting their crucial role in modern industrial operations.

Understanding Wafer Type Butterfly Valves

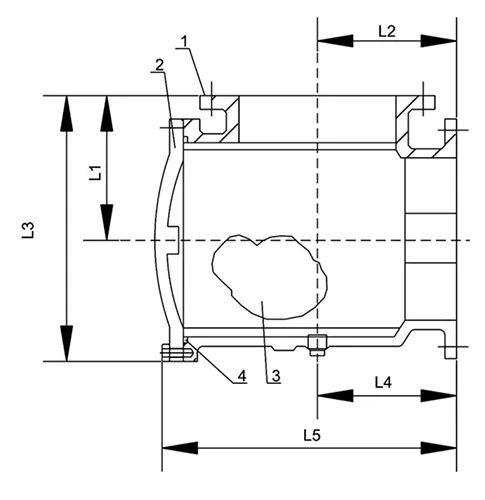

A wafer type butterfly valve is a simplistic yet efficient device used to regulate fluid flow through a pipe. The design consists of a circular disc that rotates on a vertical axis to either obstruct or allow fluid passage. One of the notable characteristics of wafer type butterfly valves is their compact and lightweight design, making them ideal for applications where space is a constraint. These valves are installed between two flanges of a pipeline and are typically secured with bolts, ensuring a tight and reliable seal.

Characteristics of Flanged Connections

Flanged connections are essential when it comes to ensuring a secure attachment between the valve and the pipeline. Flanges facilitate easy installation and maintenance, allowing for quick disassembly and replacement of the valve without significant disruptions to the entire system. This is particularly advantageous in industrial settings where system downtime can be costly. The robust design of flanged connections also withstands higher pressures and temperatures, enabling the valve to operate effectively across various demanding environments.

Advantages of Wafer Type Butterfly Valves with Flanges

1. Space Efficiency Wafer type butterfly valves are significantly thinner than traditional gate or globe valves, making them perfect for applications with limited space. This slim profile also contributes to a lighter overall system weight.

2. Low Pressure Drop The streamlined design of the butterfly disc creates minimal resistance to fluid flow, resulting in lower pressure drops across the valve. This feature is particularly beneficial in systems requiring high flow rates and efficiency.

wafer type butterfly valve flange

3. Ease of Operation Wafer type butterfly valves can be easily operated manually or with automated actuators. The simple quarter-turn operation minimizes the effort required to open or close the valve, enhancing operational efficiency.

4. Cost-Effectiveness Compared to other valve types, wafer type butterfly valves tend to be more affordable while providing excellent performance. Their ease of installation and maintenance further contributes to cost savings over the valve’s lifespan.

5. Versatility These valves are suitable for a wide range of applications, including water treatment, chemical processing, HVAC systems, and more. Their ability to handle various fluids, including slurries and gases, makes them adaptable to different sectors.

Applications of Wafer Type Butterfly Valves

Wafer type butterfly valves with flanges are extensively used in several industries. In the water and wastewater treatment sector, they play a vital role in managing flow rates and preventing backflow. In the chemical industry, their resistance to corrosive substances makes them ideal for transferring chemicals safely. HVAC systems utilize these valves to control air and fluid flow, ensuring efficient heating and cooling processes.

Moreover, their reliability and performance in high-temperature and high-pressure applications make wafer type butterfly valves essential components in power plants. In food and beverage processing, their hygienic design ensures compliance with health standards while providing accurate flow control.

Conclusion

Wafer type butterfly valves with flanged connections represent a critical advancement in fluid control technology. Their unique features, including space efficiency, low-pressure drop, and versatility, make them an indispensable choice for a vast array of industrial applications. As industries continue to evolve and require more efficient and reliable fluid control solutions, wafer type butterfly valves will undoubtedly play a significant role in shaping the future of fluid management. Emphasizing their importance not only highlights advancements in engineering but also points towards the ongoing innovations in industrial practices, paving the way for enhanced efficiency and sustainability.

Share