Jan . 20, 2025 01:15 Back to list

grooved end butterfly valve

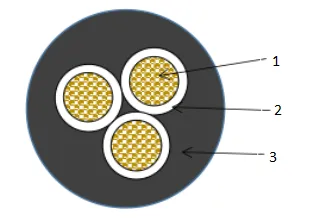

Grooved butterfly valves have emerged as pivotal components in various industrial applications, ranging from water treatment facilities to HVAC systems. Their unique design, characterized by a grooved connection, allows for ease of installation while ensuring robust performance. With the increasing need for systems to be both efficient and sustainable, understanding the intricacies of grooved butterfly valves becomes essential.

Trustworthiness is cemented in the real-world performance of grooved butterfly valves. Their ability to maintain integrity over long periods makes them a trustworthy component in systems where failures can lead to costly operational downtimes. For instance, in critical applications like fire protection systems, the valve’s contribution to system reliability cannot be overstated. It maintains consistent performance even under adverse conditions, thereby protecting assets and lives alike. The circular and groove-centric design not only ensures durability but also supports superior thermal management. When subjected to extreme temperatures, the materials used in grooved butterfly valves prevent deformation, thus extending their lifespan and reducing maintenance frequency. This aspect highlights the valve’s adaptability in diverse environments, making it a versatile choice for engineers and project managers looking to maximize system efficiency and longevity. Additionally, considering the rising environmental consciousness in industrial planning, grooved butterfly valves are lauded for their contribution to sustainability. Their design reduces material wastage during installation and maintenance, and their longevity minimizes replacement cycles, thereby reducing industrial carbon footprints. As industries move towards greener practices, such valve designs play a crucial role in supporting these transitions. In conclusion, the case for grooved butterfly valves within industrial applications is compelling. Their ease of installation, coupled with robust and reliable performance, positions them as an optimal choice for industries prioritizing efficiency and sustainability. As industries evolve and project demands become more nuanced, the choice of such components will be critical to ensuring both current operational excellence and future scalability. Industry professionals and project managers should regard the incorporation of grooved butterfly valves not just as a technical choice but as a strategic decision, aligning with broader objectives of reliability, efficiency, and sustainability.

Trustworthiness is cemented in the real-world performance of grooved butterfly valves. Their ability to maintain integrity over long periods makes them a trustworthy component in systems where failures can lead to costly operational downtimes. For instance, in critical applications like fire protection systems, the valve’s contribution to system reliability cannot be overstated. It maintains consistent performance even under adverse conditions, thereby protecting assets and lives alike. The circular and groove-centric design not only ensures durability but also supports superior thermal management. When subjected to extreme temperatures, the materials used in grooved butterfly valves prevent deformation, thus extending their lifespan and reducing maintenance frequency. This aspect highlights the valve’s adaptability in diverse environments, making it a versatile choice for engineers and project managers looking to maximize system efficiency and longevity. Additionally, considering the rising environmental consciousness in industrial planning, grooved butterfly valves are lauded for their contribution to sustainability. Their design reduces material wastage during installation and maintenance, and their longevity minimizes replacement cycles, thereby reducing industrial carbon footprints. As industries move towards greener practices, such valve designs play a crucial role in supporting these transitions. In conclusion, the case for grooved butterfly valves within industrial applications is compelling. Their ease of installation, coupled with robust and reliable performance, positions them as an optimal choice for industries prioritizing efficiency and sustainability. As industries evolve and project demands become more nuanced, the choice of such components will be critical to ensuring both current operational excellence and future scalability. Industry professionals and project managers should regard the incorporation of grooved butterfly valves not just as a technical choice but as a strategic decision, aligning with broader objectives of reliability, efficiency, and sustainability.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025