Nov . 25, 2024 15:22 Back to list

grooved butterfly valve

Exploring Grooved Butterfly Valves A Comprehensive Overview

In the realm of fluid control systems, valves play a pivotal role, and among them, the grooved butterfly valve stands out for several reasons. Recognized for its efficiency and versatility, this type of valve is widely employed across various industries, including water treatment, oil and gas, and chemical processing. In this article, we will explore the characteristics, advantages, applications, and installation considerations of grooved butterfly valves.

What is a Grooved Butterfly Valve?

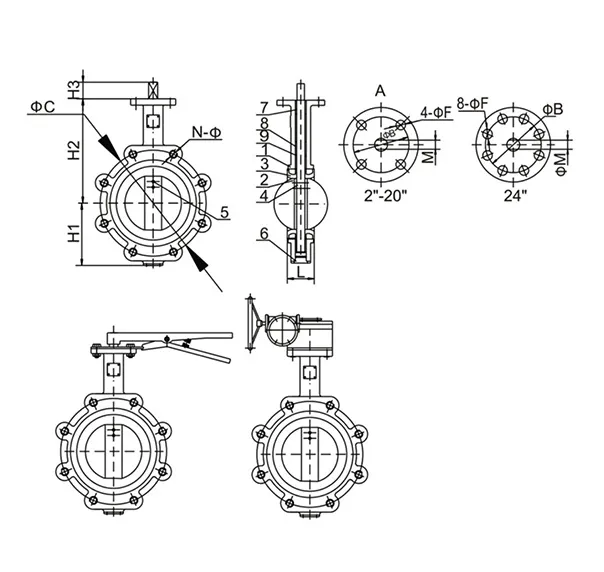

A grooved butterfly valve is a type of quarter-turn valve that consists of a rotating disc or plate that regulates fluid flow through a pipe. The disc is connected to a shaft, which is turned either manually or through an actuator. The grooved design refers to the grooves present on the valve body or the pipe ends, which allow for quick and easy installation and removal. This feature enhances the overall functionality of the valve, making it a preferred choice for many applications.

Key Characteristics

1. Design and Construction Grooved butterfly valves typically feature a lightweight design that allows for easy handling and installation. The grooved ends eliminate the need for flanges and bolting, which simplifies the piping assembly.

2. Materials These valves are commonly made from various materials, including cast iron, stainless steel, and plastic, providing options for different fluid types and operating conditions.

3. Operation The operation of a butterfly valve is straightforward. When the handle or actuator is turned, the disc rotates, either allowing or restricting flow. The simplicity of this mechanism contributes to its reliability and ease of use.

4. Sealing Grooved butterfly valves are designed with seals that ensure minimal leakage, enhancing their performance in controlling fluid flow.

Advantages of Grooved Butterfly Valves

- Space Efficiency The compact design of grooved butterfly valves makes them ideal for applications where space is limited. They require less room compared to traditional valve types, making them suitable for crowded installations.

- Quick Installation The grooved connection allows for faster installation and maintenance. Users can easily connect or disconnect the valve from the piping system, reducing downtime during repairs or replacements.

- Versatile Applications These valves are highly versatile and can be used in various environments, from municipal water systems to industrial processes. Their ability to handle different fluid types and operating pressures makes them adaptable to many settings.

- Cost-Effective Although initial costs can vary based on material and design, the overall lifecycle cost of grooved butterfly valves is often lower due to their durability and low maintenance requirements

.grooved butterfly valve

Applications

Grooved butterfly valves find applications in numerous industries, including

- Water and Wastewater Treatment They are commonly used in treatment plants for regulating water flow and controlling pressure.

- Chemical Processing The ability to handle corrosive fluids makes these valves suitable for chemical manufacturing environments.

- Oil and Gas In this industry, grooved butterfly valves are essential for controlling the flow of crude oil, natural gas, and various petrochemicals.

- HVAC Systems These valves are also employed in heating, ventilation, and air conditioning systems to manage flow rates effectively.

Installation Considerations

When installing grooved butterfly valves, several factors should be considered

- Pipe Compatibility Ensure that the valve’s connection size matches the piping system’s diameter.

- Orientation Correct orientation during installation is critical to ensure optimal operation and prevent flow turbulence.

- Pressure Ratings Verify that the valve is rated for the specific pressure and temperature conditions of the application.

- Regular Maintenance Regular inspections and maintenance are necessary to ensure the valve continues to operate efficiently. Check for signs of wear and tear on seals and the disc.

Conclusion

Grooved butterfly valves are an integral part of modern fluid control systems, combining simplicity, efficiency, and versatility. Their distinctive grooved design facilitates fast installation and maintenance, making them a favorite among engineers and technicians. Whether in water treatment, chemical processing, or HVAC systems, these valves provide a reliable solution for managing fluid flow. As industries continue to evolve, the importance of efficient and effective valve solutions like the grooved butterfly valve will undoubtedly increase.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025