Dec . 04, 2024 15:57 Back to list

Exploring the Benefits of Dual Flap Non-Return Check Valves for Fluid Systems

Understanding Dual Flap Check Valves A Comprehensive Overview

Dual flap check valves are essential components in various industrial and residential fluid systems, designed to prevent backflow and ensure the efficient operation of piping systems. They are particularly valued in applications that require a reliable and efficient means of controlling the flow of fluids while minimizing the risk of reverse flow, which can lead to system failures, inefficiencies, and costly damages.

What is a Dual Flap Check Valve?

A dual flap check valve, also known as a dual-plate check valve, utilizes two hinged flaps or plates to regulate fluid flow. These flaps operate automatically, allowing fluid to flow in a designated direction while closing in the event of a reverse flow, thus preventing backflow. Unlike standard single flap check valves, the dual flap design enhances performance by distributing fluid pressure evenly across both plates, leading to improved sealing and reduced turbulence within the system.

Key Features and Advantages

1. Efficient Flow Control The primary advantage of a dual flap check valve is its ability to provide effective flow control. The dual flaps open quickly when fluid flows in the intended direction, which minimizes pressure loss and maintains system efficiency.

2. Compact Design These valves are often more compact than traditional check valves, making them suitable for installations where space is limited. Their design allows for easier integration into existing systems without significant modifications.

3. Reduced Water Hammer One of the major issues in fluid systems is water hammer, a phenomenon caused by sudden changes in fluid flow. The dual plates of the check valve help mitigate these issues by providing a smoother transition when the valves close, reducing the shock waves and potential damage to the system.

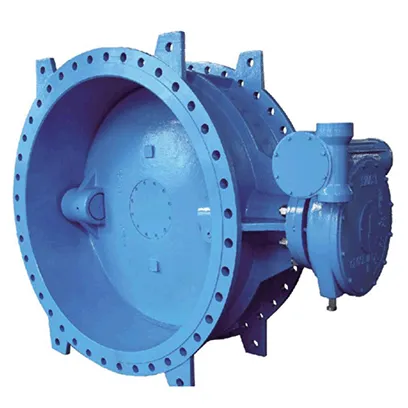

dual flap check valve

4. Durability and Reliability Dual flap check valves are typically constructed from robust materials, such as stainless steel, ductile iron, or PVC, ensuring longevity and resistance to corrosion. Their robust construction makes them suitable for high-pressure applications, including water treatment plants and industrial processes.

5. Versatile Applications These valves are ideal for a wide range of applications, from municipal water systems and fire protection systems to oil and gas pipelines. Their adaptability makes them a preferred choice for engineers and designers.

Installation and Maintenance

Installing a dual flap check valve requires careful consideration of the piping orientation and flow direction. It’s typically recommended to install these valves in a horizontal position, though they may also be installed vertically in specific applications. Proper alignment during installation is crucial to ensure that the flaps operate smoothly and do not encounter obstructions.

Maintenance of dual flap check valves is relatively straightforward. Regular inspection is essential to ensure that the flaps are not stuck or damaged. Notably, the valve’s internal components should be periodically cleaned to prevent debris from affecting performance. Additionally, lubricating the hinges can help maintain optimal operation and extend the valve's lifespan.

Conclusion

Dual flap check valves represent a sophisticated solution to managing fluid flow and preventing backflow in various systems. Their efficient design, combined with robust construction, ensures that they perform effectively under a wide range of conditions. For engineers, choosing the right check valve is critical, and the dual flap variant often emerges as the most reliable option, particularly in high-demand and variable environments.

Understanding the role and benefits of dual flap check valves can significantly impact the performance and reliability of fluid systems. As industries continue to evolve and demand greater efficiency, the importance of reliable flow control mechanisms like dual flap check valves will only increase. Proper installation, regular maintenance, and the use of quality components will ensure that these valves deliver optimal performance, safeguarding fluid systems against potential failures and enhancing overall operational efficiency.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025