Nov . 12, 2024 15:05 Back to list

swing type check valve

Understanding Swing Type Check Valves A Comprehensive Overview

Swing type check valves are essential components in various piping systems, primarily utilized to prevent backflow in a pipeline. They are designed to allow fluid to flow through them in one direction while automatically closing if the flow reverses. This mechanism is vital for maintaining the integrity of pumping systems and ensuring operational efficiency.

What is a Swing Type Check Valve?

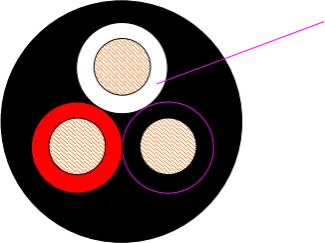

A swing type check valve operates on the principle of gravity and fluid dynamics. It consists of a disc, a seat, and a body. When the fluid flows in the correct direction, the disc swings open, allowing fluid to pass. However, if there is a reverse flow, the disc swings back into the seat due to the force of gravity, sealing the valve and preventing backflow. This design is simple yet effective, making it a preferred choice in various industrial applications.

Key Features and Benefits

1. Simple Design The straightforward construction of swing type check valves means fewer components, which often leads to lower manufacturing costs and easier maintenance.

2. Low Pressure Drop Swing check valves generally exhibit a lower pressure drop compared to other types of check valves, such as lift check valves. This property is particularly advantageous in systems where maintaining pressure is crucial.

3. Self-Operating These valves do not require any external power or manual intervention to operate. Their automatic functioning based on fluid flow significantly simplifies the overall system design.

4. Robust Construction Most swing check valves are constructed from durable materials such as stainless steel, cast iron, or brass, which enhances their longevity and reliability in different environments, including high-temperature and corrosive conditions.

5. Versatility Swing type check valves are versatile and can be used in various applications, including water supply systems, wastewater treatment plants, chemical processing, and HVAC systems.

Applications of Swing Type Check Valves

swing type check valve

Swing type check valves find applications in numerous industries due to their reliability and efficiency

. Some common uses include- Water and Wastewater Management In municipal water systems, these valves are critical in preventing backflow and ensuring clean water supply. They are also vital in sewage treatment facilities to keep wastewater flowing in the proper direction.

- Power Generation In power plants, swing check valves are used in cooling water systems and feedwater lines to prevent backflow that could cause flooding or other operational issues.

- Oil and Gas The oil and gas industry utilizes swing check valves in pipelines and drilling systems to maintain the flow direction of crude oil, natural gas, and other fluids, thus safeguarding against leaks.

- Food and Beverage The food industry requires stringent hygiene standards, and swing type check valves ensure the safe direction of fluid flow in processing lines, preventing contamination.

Installation and Maintenance

Proper installation and regular maintenance are crucial for the optimal performance of swing type check valves. It is essential to install the valve in the correct orientation, as indicated by the manufacturer's installation guides. Additionally, periodic inspection for wear and tear is advisable to ensure that the disc seats properly and operates smoothly.

Over time, deposits can accumulate on the disc or seat, potentially impeding functionality. Regular cleaning and maintenance checks can help prolong the life of the valve and maintain system efficiency.

Conclusion

Swing type check valves are critical components in modern engineering, providing reliability and efficiency in fluid control systems. Their simple yet effective design, combined with their low pressure drop characteristic and ease of operation, make them a popular choice across various industries. Understanding their function, applications, and maintenance requirements can help engineers and operators ensure optimal performance and longevity in their operations. As industries continue to advance, the importance of robust and efficient flow control solutions like swing type check valves will undoubtedly persist.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025