Nov . 25, 2024 15:12 Back to list

Understanding the Function and Importance of Hydraulic Control Valves in Fluid Systems

Understanding Hydraulic Control Valves

Hydraulic control valves are essential components in hydraulic systems, playing a critical role in regulating the flow and pressure of hydraulic fluids. They ensure that machinery operates efficiently and safely, making them vital in various applications, from industrial machinery to mobile equipment.

At its core, a hydraulic control valve functions by directing the fluid flow and adjusting pressure levels within a system. This regulation is achieved through various mechanisms, such as spool valves, poppet valves, and rotary valves. Each design serves specific purposes and is chosen based on the application's requirements.

One of the primary types of hydraulic control valves is the directional control valve. This valve manages the flow direction of the hydraulic fluid, allowing operators to control the movement of actuators, such as hydraulic cylinders and motors. By altering the position of the valve's spool, the operator can change the path of the fluid, enabling precise control over machinery movements.

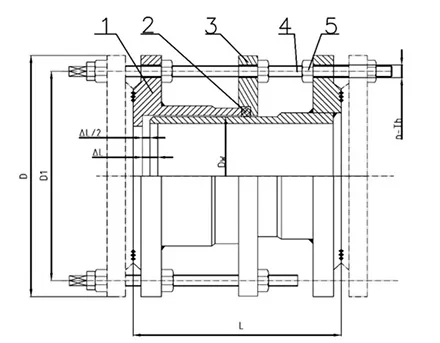

hydraulic control valve

Another crucial type is the pressure control valve, which maintains the system's pressure within safe limits. These valves can be categorized into relief valves, which prevent excessive pressure buildup, and reducing valves, which lower the pressure for specific circuit components. Maintaining proper pressure is vital for preventing hydraulic system failures and ensuring the longevity of equipment.

Flow control valves are also significant in hydraulic systems, regulating the speed of actuators by controlling the fluid flow rate. By adjusting the flow, operators can fine-tune the speed of machinery operations, enhancing productivity and ensuring smooth performance.

The selection of hydraulic control valves involves consideration of several factors. These include the type of fluid used, the expected flow rates, the operating pressure range, and the specific needs of the application. Proper selection and maintenance are paramount, as poorly functioning valves can lead to inefficiencies, increased wear on components, and potential system failures.

In conclusion, hydraulic control valves are indispensable in modern hydraulic systems, providing essential functionality for a wide array of applications. Their ability to control flow, pressure, and direction enables smooth and efficient operation of machinery. Understanding the various types of hydraulic control valves and their applications is crucial for anyone working with hydraulic systems, ensuring optimal performance and reliability in machinery. Regular maintenance and careful selection will further enhance the system's efficiency, making hydraulic control valves a cornerstone of hydraulic technology.

Share

-

Advanced Technology in Wire and Cable FactoryNewsAug.19,2025

-

Applications of Ball Check Valve in Water Treatment PlantsNewsAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingNewsAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveNewsAug.19,2025

-

Threaded Ball Valve Pressure RatingsNewsAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisNewsAug.19,2025