Feb . 16, 2025 13:32 Back to list

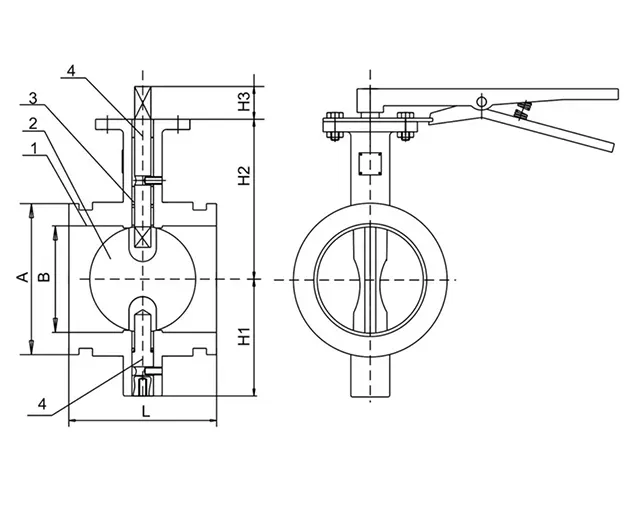

double eccentric butterfly valve

Double eccentric butterfly valves, also known as high-performance butterfly valves, have increasingly become an essential component in modern industrial applications. Their unique design not only offers enhanced control and reliability but also features distinct advantages over traditional valve systems. The engineering behind these valves ensures that they are capable of handling high-pressure and high-temperature situations, making them indispensable for industries ranging from oil and gas to chemical and water treatment.

Selecting the right valve requires thorough expertise, particularly regarding the specific demands of the application at hand. Professionals in the field advocate for double eccentric butterfly valves when dealing with demanding environments that necessitate both resilience and flexibility. Engineers and operators have highlighted their ease of installation and maintenance as key benefits, alongside their ability to fit various actuation systems, which further underscores their user-friendly nature. Trustworthiness is inherent to the leading manufacturers of double eccentric butterfly valves. Established brands, with years of experience, dedicate their efforts to continuous improvement and cutting-edge innovation. Adopting these valves from reputable sources ensures that quality standards are met and that they pass rigorous testing necessary to uphold industry standards and certifications. Such credibility is paramount, as it reassures industries of the reliability and safety of their key operational components. The deployment of double eccentric butterfly valves represents a commitment to precision engineering—a commitment that industrial stakeholders recognize as vital to their strategic operations. For decision-makers in sectors reliant on robust flow control mechanisms, these valves provide a formidable solution. The authoritative reputation of these valves coalesces with practical experiences to create a compelling narrative of excellence in fluid management solutions. As industrial challenges evolve, so too must the tools and components that drive these sectors forward. The double eccentric butterfly valve stands as a testament to the progress in valve technology, paving the way for future innovations that promise greater efficiencies and higher performance. Their role as a cornerstone device in industrial applications continues to expand, ensuring that they remain an integral part of the operational backbone for many critical industries worldwide.

Selecting the right valve requires thorough expertise, particularly regarding the specific demands of the application at hand. Professionals in the field advocate for double eccentric butterfly valves when dealing with demanding environments that necessitate both resilience and flexibility. Engineers and operators have highlighted their ease of installation and maintenance as key benefits, alongside their ability to fit various actuation systems, which further underscores their user-friendly nature. Trustworthiness is inherent to the leading manufacturers of double eccentric butterfly valves. Established brands, with years of experience, dedicate their efforts to continuous improvement and cutting-edge innovation. Adopting these valves from reputable sources ensures that quality standards are met and that they pass rigorous testing necessary to uphold industry standards and certifications. Such credibility is paramount, as it reassures industries of the reliability and safety of their key operational components. The deployment of double eccentric butterfly valves represents a commitment to precision engineering—a commitment that industrial stakeholders recognize as vital to their strategic operations. For decision-makers in sectors reliant on robust flow control mechanisms, these valves provide a formidable solution. The authoritative reputation of these valves coalesces with practical experiences to create a compelling narrative of excellence in fluid management solutions. As industrial challenges evolve, so too must the tools and components that drive these sectors forward. The double eccentric butterfly valve stands as a testament to the progress in valve technology, paving the way for future innovations that promise greater efficiencies and higher performance. Their role as a cornerstone device in industrial applications continues to expand, ensuring that they remain an integral part of the operational backbone for many critical industries worldwide.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025