Nov . 11, 2024 17:07 Back to list

control valve

Understanding Control Valves Essential Components in Modern Industries

Control valves play a crucial role in numerous industries, including water treatment, oil and gas, pharmaceuticals, and chemical manufacturing. These devices are fundamental in regulating the flow and pressure of liquids and gases, thereby ensuring smooth operations and protecting equipment from damage.

At its core, a control valve adjusts the flow rate or pressure of a fluid by changing its size, thereby regulating the amount of fluid that passes through. This is critical for maintaining the desired process conditions and ensuring that systems operate efficiently. The primary function of a control valve is to provide precise control over variables such as flow rate, temperature, level, and pressure.

Types of Control Valves

Control valves come in various types, each designed for specific applications. The most common types include

1. Globe Valves These valves have a spherical body and are known for their good throttling capabilities. They are often used in applications where flow needs to be regulated precisely.

2. Ball Valves These valves utilize a spherical disc to control flow. They are favored for their quick opening and closing capabilities, making them ideal for on-off services rather than throttling.

3. Butterfly Valves Butterfly valves consist of a rotating disc that regulates flow. They are lightweight and compact, making them suitable for large volume applications and often used in water supply and wastewater treatment.

4. Gate Valves While primarily used for on/off control, gate valves are not suitable for throttling purposes. They are often found in pipelines where a quick shut-off is necessary.

5. Check Valves These valves prevent backflow in a system. They allow fluid to flow in one direction and are critical for protecting pumps and compressors from reverse flow.

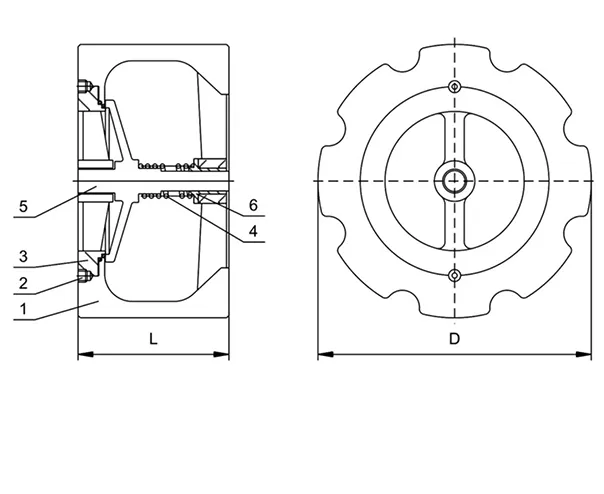

Components of a Control Valve

control valve

A typical control valve system comprises several components, including the valve body, actuator, positioner, and trim

.- Valve Body The main part of the valve that houses the internal mechanisms and provides the pathway for the fluid. Its design greatly influences the valve's performance characteristics.

- Actuator The actuator enables the valve to open or close. Electric, pneumatic, or hydraulic actuators can be employed, depending on the application and required response speed.

- Positioner This component adjusts the position of the valve based on the control signal it receives. It ensures the valve reaches the desired position quickly and accurately, maintaining the setpoint of the process variable.

- Trim The internal parts that come into contact with the fluid, including the plug, seat, and stem. The trim design affects the flow characteristics and performance of the valve.

The Importance of Control Valves in Industry

Control valves are critical for managing plant safety, efficiency, and product quality. Improperly functioning valves can lead to catastrophic failures, resulting in safety hazards, unplanned downtime, and financial losses. To prevent such incidents, regular maintenance and testing of control valves are essential.

Moreover, with the rise of automation and smart technologies in industrial applications, control valves are becoming increasingly advanced. Integration with digital control systems allows for real-time monitoring and adjustments, helping facilities to optimize their processes, reduce energy consumption, and minimize waste.

Conclusion

In summary, control valves are indispensable components in modern industrial systems. Their ability to regulate fluid flow and pressure ensures that processes run smoothly, efficiently, and safely. As technology continues to evolve, so too will the design and function of control valves, paving the way for smarter, more efficient industrial operations. Understanding the intricacies of control valves not only enhances process control but also plays a vital role in improving overall system reliability and sustainability.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025