Nov . 27, 2024 19:09 Back to list

Semi-Lugged Butterfly Valve Applications and Advantages in Efficient Fluid Control Systems

Understanding Semi-Lugged Butterfly Valves A Comprehensive Overview

In the realm of industrial fluid control, butterfly valves play a pivotal role due to their design, efficiency, and versatility. Among the various types of butterfly valves, the semi-lugged butterfly valve has gained popularity for its unique features and suitability across diverse applications. This article delves into the design, operational principles, advantages, and typical applications of semi-lugged butterfly valves.

Design Features

Semi-lugged butterfly valves are characterized by their specific body design, which combines features from both lugged and wafer butterfly valves. Unlike fully lugged valves that are equipped with threaded lugs that allow the valve body to be bolted directly to the pipe flanges, semi-lugged valves possess a partial lug configuration. This unique structure facilitates easier installation and removal from the pipeline without the need for complex additional apparatuses.

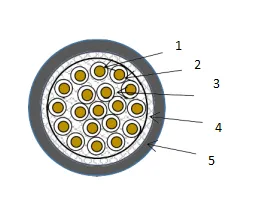

The valve body is typically made from robust materials such as cast iron, stainless steel, or ductile iron, providing durability against high pressures and aggressive media. The disc, which is the core component responsible for controlling flow, rotates within the valve body and is typically engineered for optimal flow characteristics and minimal pressure loss.

Operational Principles

The operation of a semi-lugged butterfly valve is straightforward. The valve comprises a circular disc that is mounted on a rotating shaft. When the valve is in the closed position, the disc spans the entire cross-section of the pipeline, effectively blocking fluid flow. By rotating the disc (via the shaft) to an open position, the valve allows fluid to pass through, with the disc aligned parallel to the flow direction.

The semi-lug design supports flexibility during installation, allowing the valve to be installed between two flanged connections with ease, which is particularly advantageous in tight spaces or systems requiring frequent maintenance. This design minimizes the stress on the pipe, making it a preferred choice for various fluid transfer applications.

Advantages

The semi-lugged butterfly valve offers several advantages over other valve types

semi lugged butterfly valve

1. Easy Installation and Maintenance Its design allows for quicker installation in new systems and straightforward maintenance, reducing downtime in operations.

2. Space Efficiency The compact nature of these valves contributes to space-saving in tight installations, making them ideal for plants and facilities where equipment density is high.

3. Cost-Effectiveness Compared to other valve types, semi-lugged butterfly valves are generally less expensive, making them an economical option for numerous applications.

4. Versatile Application Range These valves can handle various media, including water, gas, and certain chemicals, catering to different industrial needs.

5. Low Operating Torque The design minimizes the effort needed to operate the valve, providing energy savings in automated systems.

Applications

Due to their benefits, semi-lugged butterfly valves find their use in a wide range of industries, including

- Water Treatment Plants Managing the flow of water and wastewater efficiently. - Food and Beverage Industry Ensuring hygiene and compliance with industry standards while controlling the flow of liquids. - Chemical Processing Handling various fluids safely, including corrosive chemicals, thanks to the durability of the materials used. - HVAC Systems Controlling airflow in heating, ventilation, and air conditioning systems effectively. - Oil and Gas Sector Managing the flow of oil and natural gas in pipelines.

Conclusion

In the ever-evolving industrial landscape, the need for reliable, efficient, and cost-effective solutions drives innovation in valve technology. The semi-lugged butterfly valve stands out as an excellent choice, combining the advantages of design simplicity with high functionality. Its ability to cater to various applications while maintaining ease of installation and maintenance makes it a valuable asset for engineers and operators alike. As industries continue to seek improved systems for fluid control, the semi-lugged butterfly valve will undoubtedly remain an indispensable component in many pipelines worldwide. Whether in water treatment facilities or chemical processing plants, these valves exemplify efficiency and reliability in modern engineering practices.

Share

-

priming-a-pump-with-a-foot-valve-with-strainerNewsAug.23,2025

-

the-importance-of-a-y-strainer-in-pump-protectionNewsAug.23,2025

-

stainless-steel-ball-check-valve-for-high-purity-applicationsNewsAug.23,2025

-

common-applications-for-wafer-type-butterfly-valvesNewsAug.23,2025

-

seat-options-for-a-12-inch-knife-gate-valveNewsAug.23,2025

-

the-lifespan-of-a-typical-dismantling-jointNewsAug.23,2025