Dec . 07, 2024 06:17 Back to list

rubber expansion joint flange type

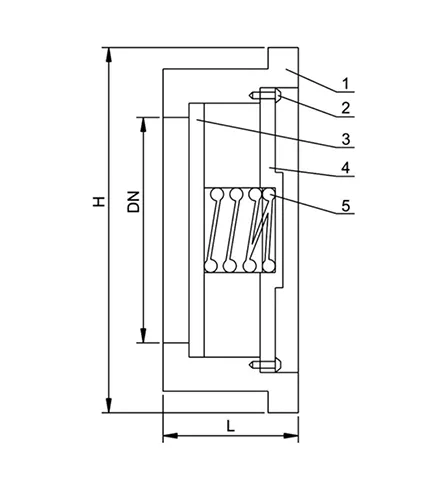

Understanding Rubber Expansion Joint Flange Types

Rubber expansion joints are crucial components in various industrial applications. They are designed to absorb vibrations, accommodate thermal expansion, and reduce noise in piping systems. Among the various configurations of these joints, the flange type is particularly important due to its widespread usage and efficiency in installation and operation. This article delves into the characteristics, advantages, and applications of rubber expansion joint flange types.

What are Rubber Expansion Joints?

Rubber expansion joints, also known as flexible connectors, are made from elastomeric materials that possess excellent flexibility, durability, and resistance to a wide range of temperatures and chemicals. These joints are engineered to provide a flexible connection between two rigid structures, typically piping systems. By allowing for motion in multiple directions—such as axial, lateral, and angular movements—rubber expansion joints minimize stress on pipes and flanges induced by thermal expansion, vibrations, and misalignments.

Flange Types of Rubber Expansion Joints

The flange type of rubber expansion joint features flanged ends that enable easy installation into existing piping systems. These joints can be manufactured with various flange standards, including ANSI, DIN, and JIS, making them adaptable to different piping configurations. Common types of flanges include

1. Flat Face Flanges Designed for applications where bolts grip directly on the rubber surface. Ideal for low-pressure applications.

2. Raised Face Flanges Featuring a raised area around the bolt holes, these flanges provide better sealing and are suitable for higher-pressure applications.

3. Lugged Flanges These flanges incorporate additional lugs for mounting, providing stability and robust performance in high-vibration environments.

4. Slip-On Flanges Designed to slip over the end of the pipe and weld into place, these flanges provide flexibility while simplifying installation.

Advantages of Rubber Expansion Joints with Flanges

rubber expansion joint flange type

1. Ease of Installation The flange design allows for quick and secure installation into existing piping systems, making maintenance and replacements relatively straightforward.

2. Flexibility and Movement Absorption These joints can absorb thermal expansion and vibrations effectively, reducing stress on the piping system and minimizing the risk of leaks or failures.

3. Versatility Available in various sizes and designs, rubber expansion joints can be customized to fit specific requirements and different piping standards.

4. Cost-Effectiveness Implementing rubber expansion joints can extend the lifespan of piping systems, reducing maintenance costs and the need for frequent replacements.

5. Noise and Vibration Reduction The elastic properties of rubber help dampen vibrations and reduce noise levels within piping systems, contributing to a quieter working environment.

Applications of Rubber Expansion Joint Flange Types

Rubber expansion joint flange types are extensively used across various industries, including

- Oil and Gas To manage thermal expansion and vibrations in pipelines that transport crude oil and natural gas. - Power Generation In cooling water systems and steam lines where thermal expansion is a significant concern. - Chemical Processing To accommodate the movement of pipelines conveying corrosive substances, offering reliable performance and chemical resistance. - HVAC Systems For flexible connections in ducts and piping to combat noise and vibration.

Conclusion

In summary, rubber expansion joint flange types are integral components for ensuring the efficiency and longevity of piping systems across a wide range of industries. Their design allows for flexibility, ease of installation, and effective movement absorption, catering to various operational requirements. As industries continue to prioritize reliability and efficiency, the adoption of rubber expansion joints is likely to increase, further emphasizing their importance in modern engineering solutions. Whether dealing with thermal expansion, vibrations, or the need for noise reduction, rubber expansion joints with flanges present a practical and effective solution.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025