Dec . 04, 2024 16:51 Back to list

rising stem gate valve

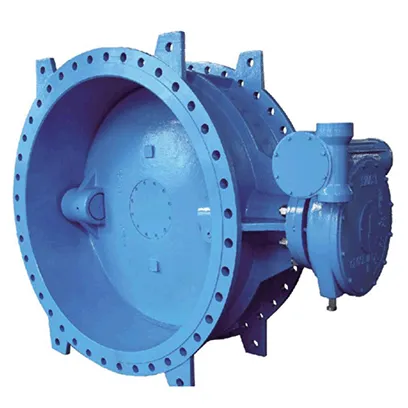

Understanding Rising Stem Gate Valves Features and Applications

Rising stem gate valves are essential components in various industrial applications, particularly in the fields of oil and gas, water treatment, power plants, and chemical manufacturing. These valves are renowned for their reliable functionality, simple design, and ease of operation. In this article, we will explore the key features of rising stem gate valves, their operational mechanisms, and their diverse applications across different industries.

Key Features

One of the defining characteristics of a rising stem gate valve is, as the name suggests, the movement of the valve stem. When the valve is opened or closed, the stem rises or falls, providing visible indication of the valve’s position. This functionality greatly enhances the operator's ability to monitor and control the flow of fluid within a system.

The construction of rising stem gate valves typically includes a gate, a seat, and a stem. The gate is the component that directly controls the flow of fluid. When the valve is fully opened, the gate is entirely out of the flow path, allowing for minimal pressure drop and reduced turbulence. Additionally, rising stem gate valves are designed to provide a tight seal when closed, preventing any leakage and ensuring the integrity of the system.

Materials used in manufacturing rising stem gate valves can vary widely depending on the application and operating conditions. Common materials include stainless steel, carbon steel, and various alloys, each offering specific advantages such as corrosion resistance or high-temperature performance.

Operational Mechanism

The operational mechanism of a rising stem gate valve is relatively straightforward. The valve is typically operated via a handwheel or actuator that turns the stem. As the handwheel is turned clockwise, the stem rises, lifting the gate out of the seat. Conversely, turning the handwheel counter-clockwise causes the stem to lower the gate back into the seat, closing off the flow.

This design not only provides a clear visual indication of whether the valve is open or closed but also contributes to the overall durability of the valve. Since the stem and gate are not subjected to excessive lateral forces during operation, rising stem gate valves tend to have a longer operational life compared to other types of valves.

rising stem gate valve

Applications

Rising stem gate valves are particularly favored in applications where a full, unobstructed flow path is critical. Some of the primary applications include

1. Water Treatment Plants These valves are widely used in water supply systems to regulate the flow of water during treatment and distribution processes. Their reliable sealing capabilities help prevent contamination.

2. Oil and Gas Industry In the extraction and transportation of oil and natural gas, rising stem gate valves are used to control flow in pipelines and processing facilities. Their durability under high pressure and temperature conditions makes them ideal for this sector.

3. Power Generation In power plants, rising stem gate valves control the flow of steam, water, and other fluids in various processes. Their ability to handle high temperatures and pressures is crucial in this environment.

4. Chemical Processing The chemical industry relies on rising stem gate valves to manage the flow of chemicals safely. Their compatibility with a variety of substances, including corrosive agents, ensures effective operation.

5. Fire Protection Systems These valves can be found in fire protection systems, providing efficient control of water flow in fire sprinkler systems.

Conclusion

Rising stem gate valves play a vital role in a myriad of industrial applications thanks to their straightforward design, effective operation, and reliable performance. Understanding their features, mechanisms, and suitable applications is essential for engineers and operators involved in fluid control systems. As industries continue to evolve and demand more efficient and safer processes, the significance of such valves is likely to grow, reinforcing their importance in modern engineering practices.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025